How can the dynamic fatigue performance of bonded solid tires be improved by optimizing the tire carcass structure to reduce the crack propagation rate?

Release Time : 2026-01-26

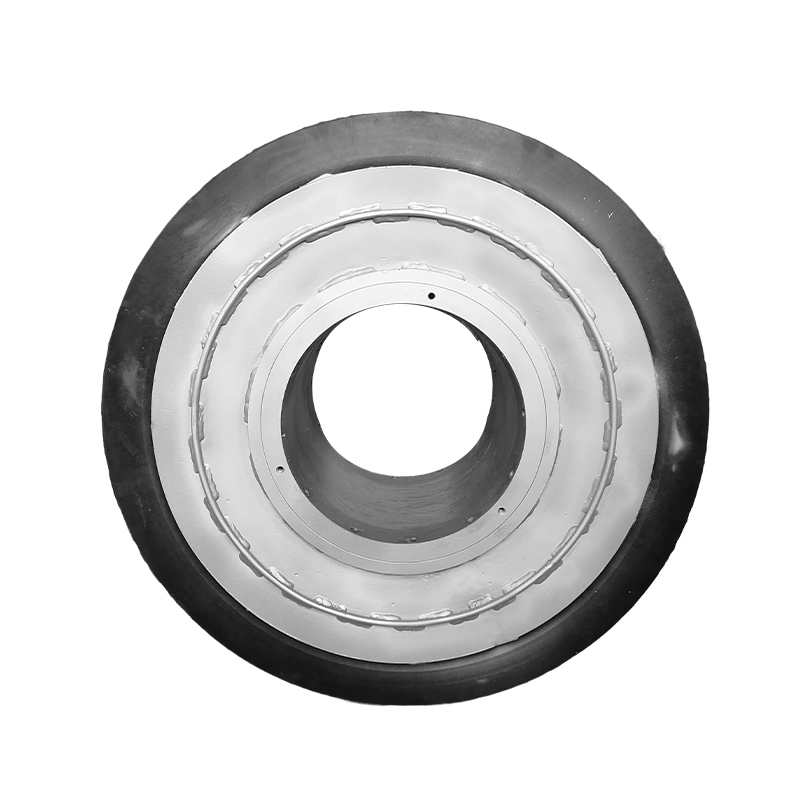

The dynamic fatigue performance of bonded solid tires is a core indicator of their long-term reliability, especially under heavy loads, high-frequency vibrations, or complex road conditions. Optimization of the tire carcass structure plays a decisive role in suppressing crack propagation rates. Crack initiation and propagation typically stem from energy dissipation of the carcass material under alternating stress, the initiation of microscopic defects, and the cumulative effect of stress concentration. Through multi-dimensional optimization of the tire carcass structure, the dynamic driving force of crack propagation can be systematically reduced from the perspectives of material distribution, geometry, interfacial bonding, and energy dispersion mechanisms, thereby extending tire life.

Gradient distribution design of the carcass material is one of the key strategies for suppressing crack propagation. Traditional solid tires mostly use homogeneous rubber structures, but the types of stresses experienced by different areas vary significantly. For example, the tread, which directly contacts the ground, needs high wear resistance and tear resistance; the sidewall needs to withstand bending deformation and shear forces; and the base of the carcass needs to balance rigidity and fatigue resistance. By creating a material property gradient along the tire carcass thickness—for example, using high-hardness, high-reinforcing filler rubber for the tread, a low-modulus, high-elasticity formulation for the sidewall, and reinforcement with fatigue-resistant agents or short fibers at the base—a "rigid-flexible" composite structure can be formed. This gradient design forces cracks to cross material interfaces with different properties during propagation, causing a deflection of the propagation path or increased energy dissipation, thus significantly reducing the crack propagation rate.

Optimizing the tire carcass geometry can effectively reduce stress concentration. Under dynamic loads, solid tires are prone to stress concentration in the shoulder, sidewall, and tread transition areas due to geometric abrupt changes, becoming "hot spots" for crack initiation. By employing rounded transitions, multi-level curved surfaces, or biomimetic designs, such as mimicking fatigue-resistant structures in nature (e.g., bamboo joints, shell layered structures), localized stress peaks can be dispersed. For example, introducing a gradual radius of curvature in the shoulder area makes the stress distribution more uniform; or designing longitudinal reinforcing ribs in the sidewall to form a "beam-plate" composite structure improves resistance to bending fatigue. These geometric optimization measures can delay crack initiation time and limit crack propagation into the deeper layers of the tire carcass.

The design of the bonding interface between the tire carcass and the rim is crucial to dynamic fatigue performance. The strength and durability of the bonding layer directly affect whether cracks will transfer from the tire carcass to the bonding interface. Optimizing the adhesive formulation (e.g., using high-toughness, aging-resistant polyurethane or modified rubber adhesives) and creating micro-roughening structures at the base of the tire carcass (e.g., laser engraving or chemical etching) can increase the bonding area and mechanical interlocking effect. Furthermore, introducing functional fillers (e.g., nano-silica or carbon fibers) into the bonding layer can form a "crack deflection layer." When a crack propagates to the bonding interface, the filler induces crack branching or changes its propagation direction, thereby consuming more energy and reducing the propagation rate of the main crack.

Multi-layered composite structures within the tire carcass are an effective means of dispersing dynamic loads. By embedding high-strength, low-density intermediate layers (e.g., aramid fiber cloth, metal mesh, or polymer composites) into the tire carcass, a synergistic effect between a "buffer layer" and a "load-bearing layer" can be formed. When a tire is subjected to impact or vibration, the intermediate layer absorbs some energy, reducing the strain amplitude of the tire carcass rubber. Simultaneously, its high modulus properties limit the overall deformation of the tire carcass, preventing crack initiation due to excessive deformation. Furthermore, the multi-layered structure dissipates energy through interlayer friction, further inhibiting crack propagation.

Protective design on the tire carcass surface can delay the erosion of dynamic fatigue performance by environmental factors. Solid tires used outdoors must withstand long-term environmental stresses such as ultraviolet radiation, ozone, and humid heat. These factors accelerate rubber aging, reduce material toughness, and thus promote crack propagation. By applying a weather-resistant coating (such as silicone rubber or fluorocarbon coating) to the tread, or using self-healing rubber materials (such as microcapsule-containing healing agents), micro-damage can be automatically filled in the early stages of cracking, preventing further crack propagation. At the same time, scratch-resistant designs on the sidewalls (such as thickened rubber layers or embedded wear-resistant strips) can reduce the sources of cracks caused by mechanical damage.

Dynamic simulation and experimental verification of the tire carcass structure are essential steps in optimizing the design. Finite element analysis (FEA) simulations of tire stress-strain distribution under dynamic loads allow for precise identification of high-risk areas and assessment of the impact of different structural parameters on crack propagation. Combined with accelerated fatigue testing (such as rotational bending fatigue testing or pulse pressure testing), the actual effectiveness of optimized designs can be verified, forming a closed-loop optimization process of "design-simulation-experiment-improvement." For example, one company reduced the crack propagation rate by introducing wavy reinforcing ribs at the tire carcass base; this achievement is based on the close integration of dynamic simulation and experimentation.

Tire carcass structure optimization must balance lightweighting and cost control. While multi-layer composites and gradient materials can significantly improve dynamic fatigue performance, excessive complexity can lead to increased manufacturing costs or weight, affecting the tire's practicality and economics. Therefore, optimized designs must strike a balance between performance improvement and engineering feasibility. This can be achieved through modular design to achieve localized reinforcement in key areas, or by using new, low-cost reinforcing materials (such as recycled fibers or bio-based rubber). This balancing strategy ensures that bonded solid tires maintain market competitiveness while improving dynamic fatigue performance.