How does the pressure applied during the bonding of trailer-bonded solid tires affect the quality?

Release Time : 2026-02-09

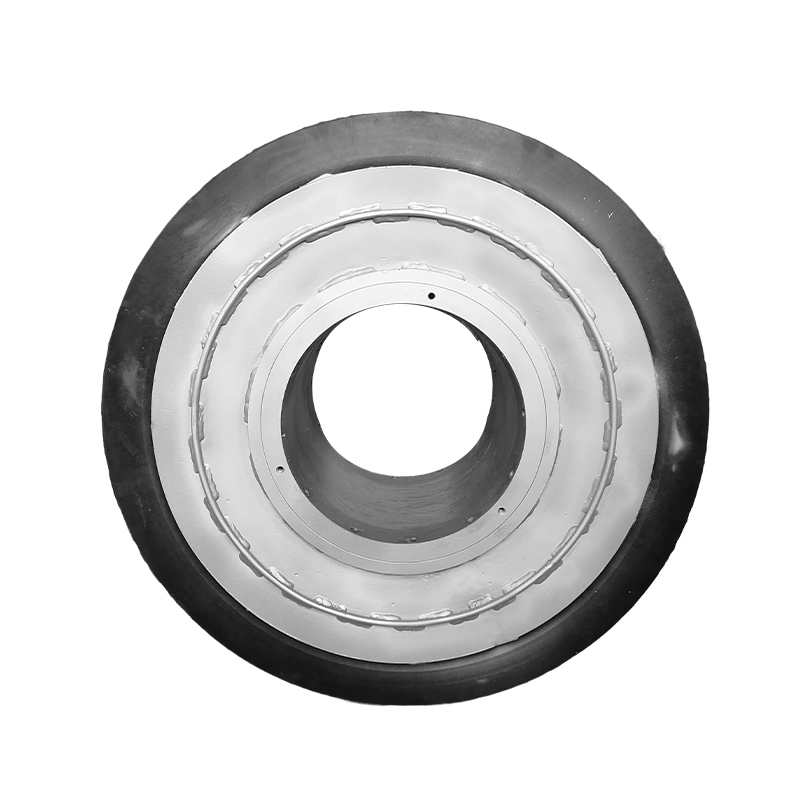

When bonded solid tir to trailers, the method of pressure application is one of the core factors affecting the bonding quality. Its function is not only to ensure a tight fit between the tire and the rim, but also to scientifically control the magnitude, direction, and duration of pressure to ensure sufficient adhesive penetration, complete removal of air bubbles, and to prevent tire or rim deformation due to localized stress concentration. Improper pressure application can lead to quality problems such as delamination, cracking, or insufficient bond strength, thereby affecting the tire's durability and safety.

In the initial stage of bonding, pressure must be evenly distributed across the entire contact surface, avoiding excessive or insufficient pressure in certain areas. Uneven pressure distribution may cause the adhesive to accumulate at the edges of the contact surface due to differences in flow resistance, resulting in an uneven state of "thick edges and thin center." In this state, insufficient adhesive in the central area leads to reduced bond strength, while excessively thick edges may generate stress due to curing shrinkage, causing delamination or cracking. Therefore, it is necessary to ensure even pressure distribution through mechanical devices or manual operation, such as using a pressing tool with a pressure sensor to monitor and adjust the pressure value in each area in real time.

The control of pressure directly affects the fusion effect between the adhesive and the substrate. Insufficient pressure prevents the adhesive from fully penetrating the tiny irregularities in the tire and rim, resulting in insufficient mechanical adhesion. Excessive pressure may extrude too much adhesive, creating gaps and increasing the risk of tire or rim deformation. For example, the rubber material of solid tires is relatively hard; if the pressure exceeds its elastic limit, it may cause permanent deformation, affecting the tire's roundness and dynamic balance. Therefore, the optimal pressure range must be determined experimentally based on the tire material, rim structure, and adhesive type, and strictly adhered to during operation.

The duration of pressure application is equally crucial. Adhesives require sufficient time to flow, penetrate, and initially cure. If pressure is released too early, the adhesive may not fully fill the gaps between the contact surfaces, leading to insufficient bond strength. If pressure is maintained for too long, the adhesive may become brittle due to over-curing, reducing impact resistance. For example, some two-component adhesives require a "gel period" and a "curing period" after mixing; pressure must cover the gel period to ensure shape stability and be maintained during the early curing stage to enhance cohesion. In practice, the adhesive instructions should be consulted, and the pressure application time adjusted according to ambient temperature and humidity.

The direction of pressure application must match the shape of the contact surfaces. For tires and rims with curved surfaces, pressure should be evenly transmitted along the normal direction of the curved surface to avoid lateral force causing tire displacement or rim deformation. For example, when bonding press-fit solid tires, the center axis of the rim and tire should be aligned first, and then pressure should be gradually applied from the center to the edge to ensure that each layer of rubber is fully adhered to the rim. Directional deviation may cause "edge lifting" or "cavities," creating potential problems for subsequent use.

Dynamic pressure adjustment can further improve bonding quality. During bonding, the fluidity of the adhesive changes with temperature and time, requiring real-time pressure adjustment based on its state. For example, in the initial stage, the adhesive has high fluidity, so the pressure can be appropriately reduced to avoid extrusion; as curing progresses, the adhesive viscosity increases, requiring gradual increase in pressure to ensure penetration. Furthermore, when using heat-assisted bonding, the pressure must be adjusted simultaneously to accommodate material thermal expansion and prevent changes in the contact surface gap due to temperature differences.

The pressure holding stage after pressure application is equally important. Holding pressure ensures that the adhesive is continuously constrained during curing, preventing internal stress caused by shrinkage. For example, some high-performance adhesives require pressure to be maintained for hours or even days to achieve deep curing. Insufficient pressure can lead to microcracks in the adhesive layer due to stress release, reducing fatigue resistance. Therefore, the pressure-holding process must be designed according to the adhesive's characteristics, and continuous constraint should be achieved using clamps or weights.

The pressure application to bonded solid tires needs to consider uniformity, magnitude, time, direction, and dynamic adjustments, and the effect should be reinforced through a pressure-holding process. Scientific control of these parameters can significantly improve bond strength, reduce the risk of air bubbles and insufficient adhesive, thereby extending tire life and ensuring safe trailer operation. In practice, it is recommended to develop a standardized pressure application procedure based on tire specifications, adhesive type, and equipment conditions, and verify the bonding quality through non-destructive testing (such as ultrasonic testing) to ensure that each step meets technical requirements.