How can air bubbles be avoided during the bonding process of bonded solid tires on a stacker crane?

Release Time : 2026-01-12

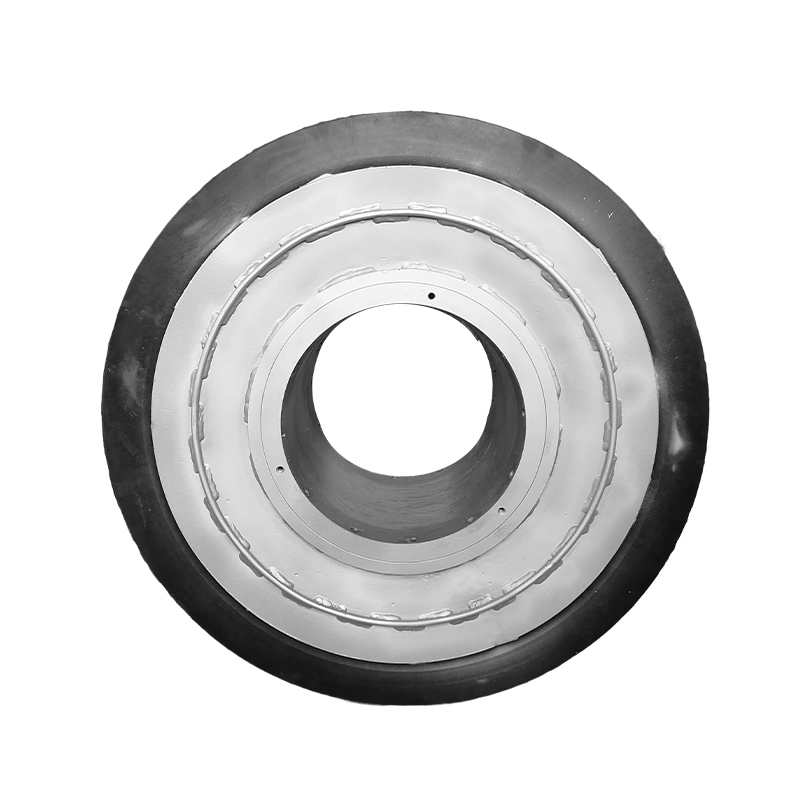

In the bonding process of stacker cranes, the formation of air bubbles can significantly affect the bonding quality, leading to delamination, accelerated wear, and even safety hazards during use. Bubble formation is mainly related to adhesive performance, process operation, environmental control, and material handling, requiring comprehensive optimization from multiple dimensions to achieve bubble-free bonding.

The selection and proportioning of the adhesive are fundamental to avoiding air bubbles. If the adhesive viscosity is too high, its flowability is poor, easily trapping air during application; if the viscosity is too low, excessive penetration may result in an insufficiently thin adhesive layer, failing to effectively fill the gaps between contact surfaces. Therefore, it is necessary to select a suitable adhesive type based on the material characteristics of the bonded solid tires and the wheel hub, and adjust the viscosity to a reasonable range through testing. Simultaneously, the curing speed and temperature sensitivity of the adhesive must match the process requirements to avoid premature curing that traps air within the adhesive layer.

The standardization of process operation directly affects the probability of air bubble formation. When applying adhesive, manual brushing can easily lead to air ingress due to uneven pressure or repeated brushing. While mechanical spraying improves uniformity, it requires careful control of spray pressure and angle to prevent air from being compressed into the adhesive layer. Furthermore, the adhesive thickness must strictly adhere to process standards; excessive thickness increases the risk of residual air bubbles, while insufficient thickness compromises bonding strength. During the assembly of bonded solid tires and wheel hubs, positioning fixtures must be used to ensure concentricity, preventing excessive gaps caused by eccentricity that provide space for air bubbles to hide.

Environmental control is crucial for reducing air bubbles. The bonding process must be carried out in a clean, dry workshop. Dust, oil, or moisture in the air can adhere to the contact surfaces, forming a barrier that hinders full contact between the adhesive and the material, leading to localized debonding and air bubble formation. Simultaneously, ambient temperature and humidity must be kept within a reasonable range. Excessively high temperatures accelerate adhesive curing, shortening processing time; excessively low temperatures may reduce adhesive fluidity, increasing the risk of air bubble ingress. High humidity may cause moisture to be absorbed by the adhesive and released during curing, forming air bubbles.

Pre-treatment of the material surface is a hidden factor in avoiding air bubbles. If the contact surface between bonded solid tires and the wheel hub has oil, oxide layers, or burrs, it will reduce the wettability of the adhesive, leading to the formation of tiny gaps between the adhesive layer and the material. Therefore, the contact surface must be thoroughly cleaned before bonding, using methods such as solvent wiping, sandblasting, or grinding to remove impurities and ensure that the surface roughness meets the requirements to enhance the mechanical bonding of the adhesive. Furthermore, if the material itself has micropores or cracks, they must be repaired beforehand to prevent gas from seeping out and forming air bubbles.

The venting operation during the bonding process needs to be precise. After the bonded solid tires are assembled with the wheel hub, the gas in the adhesive layer must be removed by mechanical pressurization or vacuum adsorption. During mechanical pressurization, the pressure must be evenly distributed to avoid excessive local pressure that could cause adhesive overflow; during vacuum adsorption, the vacuum level and time must be controlled to ensure that the gas is fully extracted. For bonded solid tires with complex structures, defoamers can be added to the adhesive to accelerate the bursting and escape of air bubbles through chemical action.

Optimizing the curing process is the final guarantee for eliminating residual air bubbles. Adhesive curing must follow a stepped temperature curve. Pre-curing at a low temperature allows the adhesive layer to initially set and expel most of the gas, before gradually increasing the temperature to the complete curing temperature. Direct high-temperature curing will cause a hard shell to quickly form on the adhesive surface, hindering the escape of internal gas and trapping air bubbles. Sufficient curing time is also crucial to avoid insufficient adhesive strength due to incomplete curing, which can lead to bubble expansion during use due to vibration or impact.

Avoiding bubble problems in bonded solid tires for stacker cranes requires a comprehensive approach, encompassing material selection, process design, environmental control, surface treatment, venting operations, and curing management. Systematic optimization and meticulous operation can significantly reduce the probability of bubble formation, improving bonding quality and the reliability of bonded solid tires.