How do bonded solid tires ensure transportation safety and efficiency under harsh working conditions?

Release Time : 2025-12-29

In industrial transportation, mining operations, and special vehicle applications, tires, as key components that directly contact the ground and bear the weight of the entire machine, directly affect the operational stability, safety, and maintenance costs of the equipment. Bonded solid tires, with their unique structural design and material processing, have become the preferred configuration for various trailers, mining trucks, forklifts, and construction machinery, especially suitable for harsh operating environments with high loads, low speeds, multiple impacts, and frequent encounters with sharp objects.

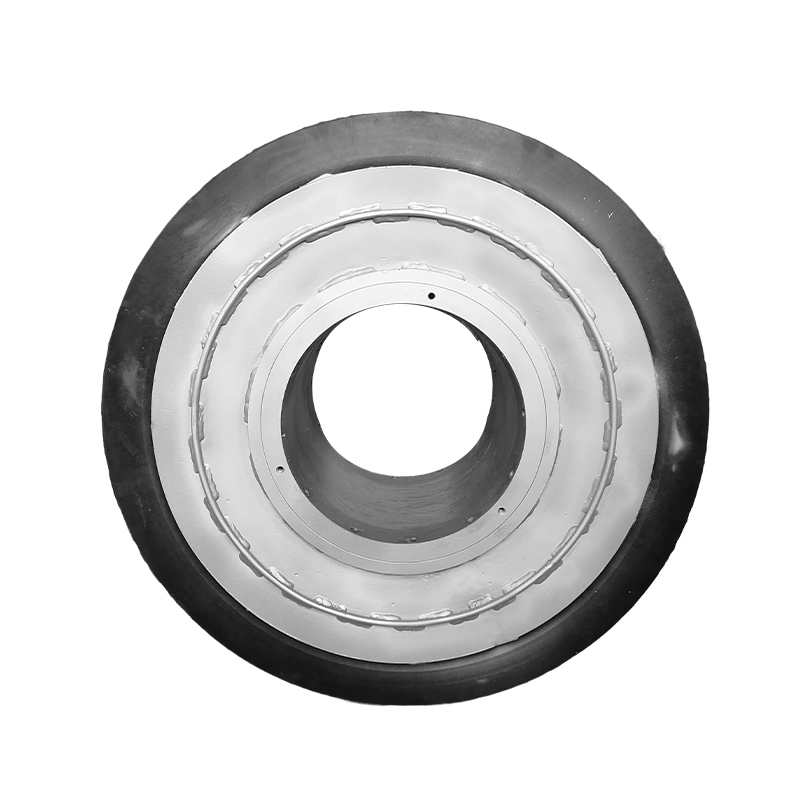

Bonded solid tires are integrally molded from high-strength steel wire rings, high-elasticity rubber treads, and multiple layers of cushioning rubber through a high-temperature, high-pressure vulcanization process. Their "solid" structure completely eliminates the internal cavity and air pressure dependence of traditional pneumatic tires. This tubeless, air-pressure-free design fundamentally eliminates common failures such as tire blowouts, slow leaks, and punctures, greatly improving reliability and safety under complex ground conditions such as gravel, metal shavings, and slag. For mining trucks, this means maintaining consistent and stable traction and support even during extended periods of operation on rough or rocky mining roads.

The "bonded" characteristic of these tires refers to the high-strength bond between the layers of the tire carcass through chemical bonds and physical cross-linking, ensuring that delamination, bulging, or cracking does not occur under dynamic loads such as repeated rolling, sudden braking, and steering. High-quality bonded solid tires typically use a composite formula of natural and synthetic rubber, balancing abrasion resistance, tear resistance, and shock absorption. Some high-end products also incorporate carbon black reinforcing agents or special polymers into the tread, making their wear life 3 to 5 times that of ordinary pneumatic tires, significantly reducing replacement frequency and downtime losses.

The advantages of bonded solid tires are equally prominent in trailer applications. Flatbed trailers, baggage carts, or material transfer vehicles in logistics parks, ports, and airports often require frequent starts and stops, on-the-spot turning, and are under heavy loads for extended periods. Using solid tires avoids uneven tire shoulder wear or rim deformation caused by insufficient tire pressure, while reducing the workload of routine tire pressure checks and maintenance. Furthermore, the solid structure provides higher rigidity, effectively suppressing vehicle sway and improving the smoothness of cargo transport.

Although bonded solid tires are slightly less comfortable than inflatable tires—due to the lack of an air cushion layer, vibration transmission is more noticeable at high speeds or on uneven surfaces—this disadvantage has minimal impact in low-speed (typically below 25 km/h) industrial vehicles. Conversely, their combined advantages of maintenance-free operation, long lifespan, and high safety make them exhibit a significantly higher life-cycle economic value than traditional tires under specific operating conditions.

Advances in manufacturing processes have also driven performance upgrades for bonded solid tires. Modern production lines commonly employ computer-controlled vulcanization systems, precisely controlling temperature, pressure, and time to ensure a high degree of consistency in the physical properties of each tire. Simultaneously, modular design allows for customization of tire width, diameter, and hardness rating based on vehicle axle load, rim specifications, and operating environment, achieving precise matching.

With the development of global mining automation, port intelligence, and green logistics, the demand for highly reliable chassis components continues to grow. Bonded solid tires, with their robustness, durability, adaptability, and ease of maintenance, are constantly expanding their application boundaries in specialized transportation equipment. In the future, with the integration of new composite materials and intelligent sensing technologies, these tires may integrate functions such as tire temperature monitoring and load feedback, further enhancing the operational intelligence of heavy-duty mobile equipment.

In summary, bonded solid tires are not simple replacements, but rather deeply optimized engineering solutions for specific industrial scenarios. With structural reliability at its core and cost-effectiveness throughout the entire lifecycle as its guiding principle, they provide a solid and durable mobile foundation for heavy equipment such as trailers and mining trucks.

Bonded solid tires are integrally molded from high-strength steel wire rings, high-elasticity rubber treads, and multiple layers of cushioning rubber through a high-temperature, high-pressure vulcanization process. Their "solid" structure completely eliminates the internal cavity and air pressure dependence of traditional pneumatic tires. This tubeless, air-pressure-free design fundamentally eliminates common failures such as tire blowouts, slow leaks, and punctures, greatly improving reliability and safety under complex ground conditions such as gravel, metal shavings, and slag. For mining trucks, this means maintaining consistent and stable traction and support even during extended periods of operation on rough or rocky mining roads.

The "bonded" characteristic of these tires refers to the high-strength bond between the layers of the tire carcass through chemical bonds and physical cross-linking, ensuring that delamination, bulging, or cracking does not occur under dynamic loads such as repeated rolling, sudden braking, and steering. High-quality bonded solid tires typically use a composite formula of natural and synthetic rubber, balancing abrasion resistance, tear resistance, and shock absorption. Some high-end products also incorporate carbon black reinforcing agents or special polymers into the tread, making their wear life 3 to 5 times that of ordinary pneumatic tires, significantly reducing replacement frequency and downtime losses.

The advantages of bonded solid tires are equally prominent in trailer applications. Flatbed trailers, baggage carts, or material transfer vehicles in logistics parks, ports, and airports often require frequent starts and stops, on-the-spot turning, and are under heavy loads for extended periods. Using solid tires avoids uneven tire shoulder wear or rim deformation caused by insufficient tire pressure, while reducing the workload of routine tire pressure checks and maintenance. Furthermore, the solid structure provides higher rigidity, effectively suppressing vehicle sway and improving the smoothness of cargo transport.

Although bonded solid tires are slightly less comfortable than inflatable tires—due to the lack of an air cushion layer, vibration transmission is more noticeable at high speeds or on uneven surfaces—this disadvantage has minimal impact in low-speed (typically below 25 km/h) industrial vehicles. Conversely, their combined advantages of maintenance-free operation, long lifespan, and high safety make them exhibit a significantly higher life-cycle economic value than traditional tires under specific operating conditions.

Advances in manufacturing processes have also driven performance upgrades for bonded solid tires. Modern production lines commonly employ computer-controlled vulcanization systems, precisely controlling temperature, pressure, and time to ensure a high degree of consistency in the physical properties of each tire. Simultaneously, modular design allows for customization of tire width, diameter, and hardness rating based on vehicle axle load, rim specifications, and operating environment, achieving precise matching.

With the development of global mining automation, port intelligence, and green logistics, the demand for highly reliable chassis components continues to grow. Bonded solid tires, with their robustness, durability, adaptability, and ease of maintenance, are constantly expanding their application boundaries in specialized transportation equipment. In the future, with the integration of new composite materials and intelligent sensing technologies, these tires may integrate functions such as tire temperature monitoring and load feedback, further enhancing the operational intelligence of heavy-duty mobile equipment.

In summary, bonded solid tires are not simple replacements, but rather deeply optimized engineering solutions for specific industrial scenarios. With structural reliability at its core and cost-effectiveness throughout the entire lifecycle as its guiding principle, they provide a solid and durable mobile foundation for heavy equipment such as trailers and mining trucks.