How do bonded solid tires meet the stable operation requirements of heavy-duty platforms weighing hundreds of tons?

Release Time : 2025-12-15

In the transport of giant sections in shipyards, the relocation of steel trusses at bridge construction sites, or the in-plant transfer of large modular equipment, heavy-duty transport platforms bear the task of moving loads of hundreds of tons or even heavier. These operations place extremely stringent requirements on the mobility system—not only must it be absolutely reliable, but it must also maintain structural stability and smooth operation without any cushioning media. Bonded solid tires were developed to meet this challenge. Their all-rubber, one-piece molding design truly possesses the ultra-high load-bearing capacity required to support platforms weighing hundreds of tons, becoming the core standard for evaluating their engineering applicability.

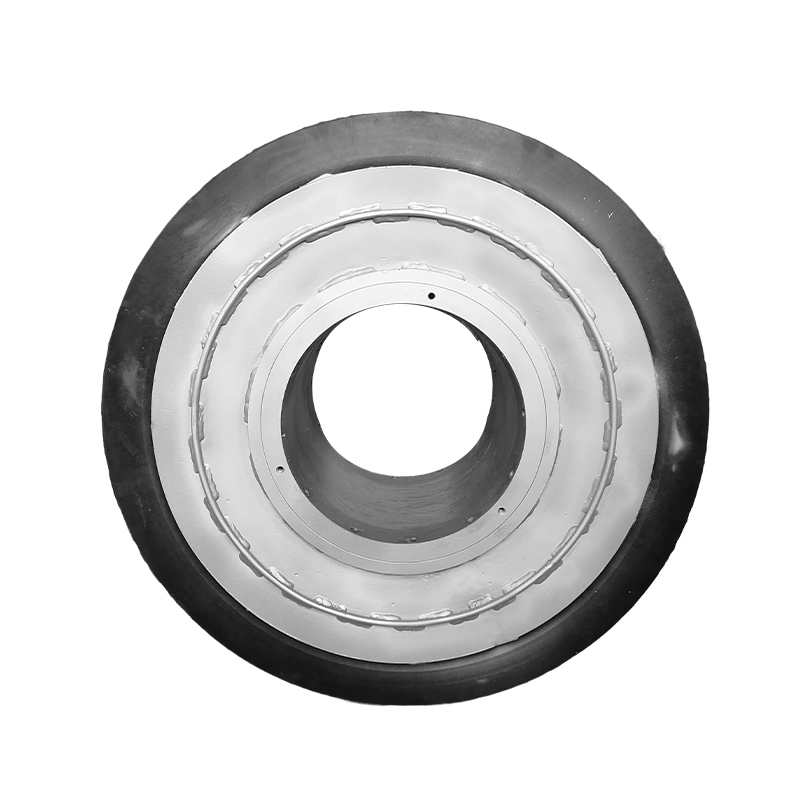

Unlike traditional pneumatic tires that rely on internal air pressure to distribute the load, bonded solid tires rely entirely on the material itself to bear the pressure. Their carcass is integrally molded from high-density, high-strength rubber through a special formula and vulcanization process, with no internal cavities, no ply layers, and no fillers, forming a dense yet elastic load-bearing unit. This "solid core equals strength" design philosophy ensures that it will not collapse due to pressure loss under extreme loads, nor will it lose function due to localized punctures. As heavy platforms slowly traverse uneven terrain, the tires absorb minor impacts through the compression and deformation of the rubber itself, while simultaneously distributing the enormous load evenly to the hubs and frame, ensuring the entire system remains stable, without swaying or tilting.

More importantly, this load-bearing capacity does not come at the expense of safety. Because it is not dependent on air pressure, solid tires completely avoid the risks of tire blowouts, slow leaks, or rim separation—risks that pneumatic tires struggled to overcome in high-temperature welding environments, shipyard decks with sharp steel edges, or bridge construction sites littered with gravel and metal scrap. The solid structure acts like a resilient rubber base; even if the surface is scratched, its overall mechanical properties remain almost unaffected, allowing it to steadily support massive loads.

Furthermore, this superior load-bearing capacity is also reflected in long-term stability. Under continuous heavy pressure, the rubber compound of high-quality solid tires is optimized for creep resistance, effectively resisting permanent deformation. This means that even after prolonged periods of static load-bearing, the tires will not flatten or develop irreversible indentations, maintaining their original geometry and rolling characteristics upon relocation. For shipbuilding trolleys or bridge launching platforms requiring precise positioning, this dimensional stability is crucial—even millimeter-level deformation can affect assembly accuracy.

From a system integration perspective, the high load-bearing capacity of solid tires also simplifies overall vehicle design. There's no need for complex air systems, tire pressure monitoring, or spare tire storage; the platform structure is simpler, and maintenance points are significantly reduced. Installation requires only bolt tightening, eliminating the need for high-pressure equipment or specialized technicians, greatly improving deployment efficiency and emergency replacement speed.

Ultimately, the ultra-high load-bearing capacity of bonded solid tires is not simply a matter of "thickening and hardening," but rather the result of a deep integration of materials science, structural mechanics, and industrial applications. It allows heavy transport to remain composed even in the harshest environments, silently bearing the displacement of steel behemoths through silent rolling—not supported by air, but by the solidity of the material itself. This is not only a victory for technology, but also the most solid interpretation of the word "reliability."

Unlike traditional pneumatic tires that rely on internal air pressure to distribute the load, bonded solid tires rely entirely on the material itself to bear the pressure. Their carcass is integrally molded from high-density, high-strength rubber through a special formula and vulcanization process, with no internal cavities, no ply layers, and no fillers, forming a dense yet elastic load-bearing unit. This "solid core equals strength" design philosophy ensures that it will not collapse due to pressure loss under extreme loads, nor will it lose function due to localized punctures. As heavy platforms slowly traverse uneven terrain, the tires absorb minor impacts through the compression and deformation of the rubber itself, while simultaneously distributing the enormous load evenly to the hubs and frame, ensuring the entire system remains stable, without swaying or tilting.

More importantly, this load-bearing capacity does not come at the expense of safety. Because it is not dependent on air pressure, solid tires completely avoid the risks of tire blowouts, slow leaks, or rim separation—risks that pneumatic tires struggled to overcome in high-temperature welding environments, shipyard decks with sharp steel edges, or bridge construction sites littered with gravel and metal scrap. The solid structure acts like a resilient rubber base; even if the surface is scratched, its overall mechanical properties remain almost unaffected, allowing it to steadily support massive loads.

Furthermore, this superior load-bearing capacity is also reflected in long-term stability. Under continuous heavy pressure, the rubber compound of high-quality solid tires is optimized for creep resistance, effectively resisting permanent deformation. This means that even after prolonged periods of static load-bearing, the tires will not flatten or develop irreversible indentations, maintaining their original geometry and rolling characteristics upon relocation. For shipbuilding trolleys or bridge launching platforms requiring precise positioning, this dimensional stability is crucial—even millimeter-level deformation can affect assembly accuracy.

From a system integration perspective, the high load-bearing capacity of solid tires also simplifies overall vehicle design. There's no need for complex air systems, tire pressure monitoring, or spare tire storage; the platform structure is simpler, and maintenance points are significantly reduced. Installation requires only bolt tightening, eliminating the need for high-pressure equipment or specialized technicians, greatly improving deployment efficiency and emergency replacement speed.

Ultimately, the ultra-high load-bearing capacity of bonded solid tires is not simply a matter of "thickening and hardening," but rather the result of a deep integration of materials science, structural mechanics, and industrial applications. It allows heavy transport to remain composed even in the harshest environments, silently bearing the displacement of steel behemoths through silent rolling—not supported by air, but by the solidity of the material itself. This is not only a victory for technology, but also the most solid interpretation of the word "reliability."