How do bonded solid tires empower intelligent industrial logistics with their airless structure and high load-bearing capacity?

Release Time : 2025-11-17

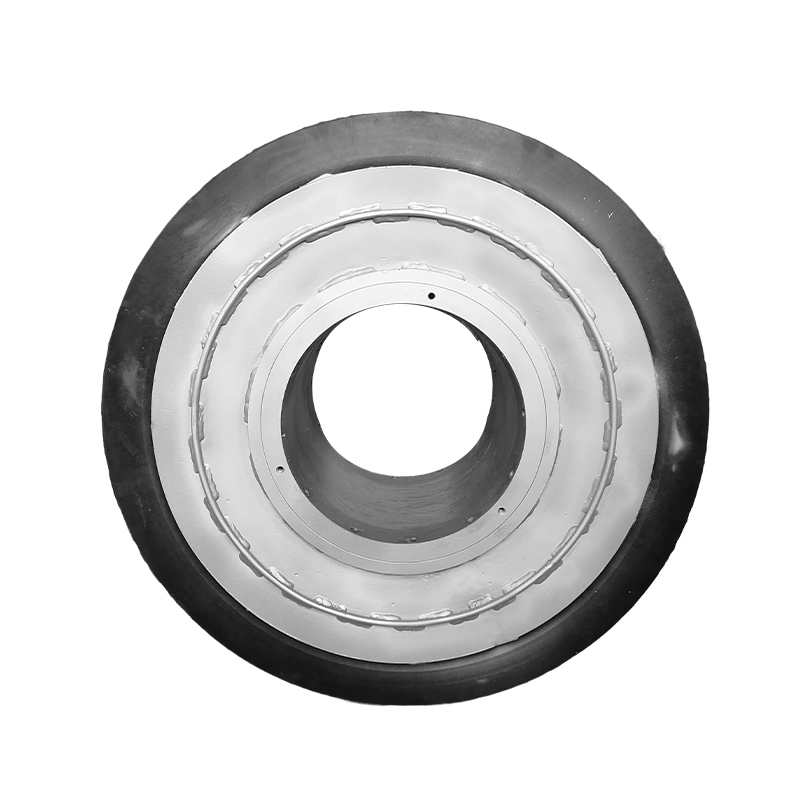

In automated warehousing, port terminals, mining operations, and intelligent manufacturing scenarios, flatbed transport equipment such as stacker cranes, heavy-duty forklifts, AGVs (Automated Guided Vehicles), IGVs (Intelligent Guided Vehicles), and ARTs (Automated Rail Transporters) place extremely high demands on tire reliability, load-bearing capacity, and operational stability. Traditional pneumatic tires are prone to blowouts and require regular maintenance, posing significant risks under heavy-load and high-frequency operating environments. Bonded solid tires—molded from a single piece of high-elasticity rubber and a high-strength steel rim through a hot vulcanization process—have become the ideal choice for modern industrial vehicles due to their airless construction, high load capacity, long lifespan, and low rolling resistance, providing robust and reliable mobility for unmanned and continuous operations.

The core advantages of bonded solid tires are primarily reflected in their superior structural strength and load-bearing capacity. Utilizing a multi-layered high-density polyester cord or steel cord reinforced carcass, combined with a high-hardness base rubber and buffer layer design, a single tire can achieve a rated load of over 3 tons, suitable for frequent starts and stops, sharp turns, and incline operation under full load conditions. The tread rubber compound is specially optimized, with a Shore hardness typically between 70 and 85A, balancing abrasion resistance and ground grip. It maintains stable traction on concrete, steel plates, gravel, and even oily surfaces, effectively preventing slippage or rollover.

Maintenance-free characteristics significantly improve operational efficiency. The absence of internal air chambers completely eliminates the risk of punctures, slow leaks, or blowouts, making it particularly suitable for warehouses with scattered sharp materials, steel mills with high-temperature molten slag environments, or dusty mines. No need for regular tire pressure checks, inflation, or inner tube replacements, significantly reducing equipment downtime and maintenance costs. This advantage is especially crucial in intelligent logistics centers operating 24/7, ensuring the AGV fleet operates efficiently year-round.

The bonding process ensures a permanent and secure bond between the rim and the rubber. Through hot vulcanization, pre-formed rubber bushings are chemically cross-linked with precision-machined cast or forged steel rims under high temperature and pressure, forming irreversible molecular bonds. This results in shear strength far exceeding that of mechanically pressed solid tires. Even under extreme torque impacts or high-speed steering, "bead slippage" or "slippage" will not occur, ensuring precise and reliable power transmission. The rim surface is sandblasted and phosphated to further enhance the durability of the bonding interface.

Rolling smoothness and noise control are continuously optimized. Despite their solid structure, modern bonded solid tires utilize asymmetrical tread patterns, a gradient design for the buffer layer, and a low-hysteresis rubber compound to effectively absorb road vibrations. Rolling noise is reduced by 10–15 decibels compared to traditional solid tires, improving operator comfort. Some high-end models also integrate polyurethane composite treads, providing a near-pneumatic tire feel while maintaining high load capacity, making them suitable for cleanrooms or precision instrument transportation scenarios.

Ultimately, the value of bonded solid tires lies not only in "supporting the vehicle," but also in their silent rubber body safeguarding safety and efficiency in every meter of intelligent logistics. When an AGV precisely navigates a warehouse late at night, or a heavy-duty forklift steadily lifts containers at a port, these maintenance-free tires are silently bearing immense pressure. In today's era of deep integration between Industry 4.0 and green manufacturing, high-performance bonded solid tires, with their reliability, durability, and intelligent adaptability, are continuously driving global material handling systems towards a higher level of automation and a sustainable future.

The core advantages of bonded solid tires are primarily reflected in their superior structural strength and load-bearing capacity. Utilizing a multi-layered high-density polyester cord or steel cord reinforced carcass, combined with a high-hardness base rubber and buffer layer design, a single tire can achieve a rated load of over 3 tons, suitable for frequent starts and stops, sharp turns, and incline operation under full load conditions. The tread rubber compound is specially optimized, with a Shore hardness typically between 70 and 85A, balancing abrasion resistance and ground grip. It maintains stable traction on concrete, steel plates, gravel, and even oily surfaces, effectively preventing slippage or rollover.

Maintenance-free characteristics significantly improve operational efficiency. The absence of internal air chambers completely eliminates the risk of punctures, slow leaks, or blowouts, making it particularly suitable for warehouses with scattered sharp materials, steel mills with high-temperature molten slag environments, or dusty mines. No need for regular tire pressure checks, inflation, or inner tube replacements, significantly reducing equipment downtime and maintenance costs. This advantage is especially crucial in intelligent logistics centers operating 24/7, ensuring the AGV fleet operates efficiently year-round.

The bonding process ensures a permanent and secure bond between the rim and the rubber. Through hot vulcanization, pre-formed rubber bushings are chemically cross-linked with precision-machined cast or forged steel rims under high temperature and pressure, forming irreversible molecular bonds. This results in shear strength far exceeding that of mechanically pressed solid tires. Even under extreme torque impacts or high-speed steering, "bead slippage" or "slippage" will not occur, ensuring precise and reliable power transmission. The rim surface is sandblasted and phosphated to further enhance the durability of the bonding interface.

Rolling smoothness and noise control are continuously optimized. Despite their solid structure, modern bonded solid tires utilize asymmetrical tread patterns, a gradient design for the buffer layer, and a low-hysteresis rubber compound to effectively absorb road vibrations. Rolling noise is reduced by 10–15 decibels compared to traditional solid tires, improving operator comfort. Some high-end models also integrate polyurethane composite treads, providing a near-pneumatic tire feel while maintaining high load capacity, making them suitable for cleanrooms or precision instrument transportation scenarios.

Ultimately, the value of bonded solid tires lies not only in "supporting the vehicle," but also in their silent rubber body safeguarding safety and efficiency in every meter of intelligent logistics. When an AGV precisely navigates a warehouse late at night, or a heavy-duty forklift steadily lifts containers at a port, these maintenance-free tires are silently bearing immense pressure. In today's era of deep integration between Industry 4.0 and green manufacturing, high-performance bonded solid tires, with their reliability, durability, and intelligent adaptability, are continuously driving global material handling systems towards a higher level of automation and a sustainable future.