How to ensure adhesion of bonded solid tires on trailers after multiple disassembly and reassembly?

Release Time : 2025-11-03

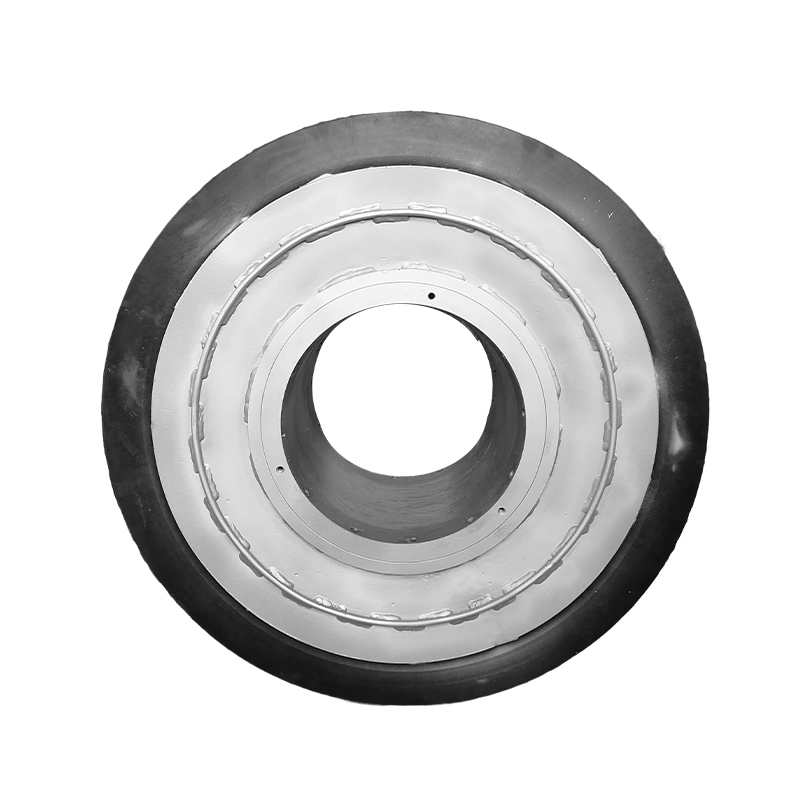

For trailer-mounted bonded solid tires, the stability of their adhesive performance after repeated disassembly and reassembly is crucial for ensuring driving safety and equipment reliability. Because bonded solid tires lack an inner tube structure, their adhesive strength directly depends on the bonding force between the tire and the rim. Repeated disassembly and reassembly can easily lead to wear of the adhesive layer, damage to the rim surface, or the intrusion of impurities, ultimately causing adhesive failure. Therefore, a comprehensive approach is needed, encompassing material selection, process control, operational procedures, and post-installation maintenance, to extend the adhesive lifespan.

Choosing a suitable adhesive is fundamental. Bonding bonded solid tires to the rim requires a specialized adhesive with components that balance high elasticity, aging resistance, and temperature resistance. For example, adhesives containing polyurethane or modified rubber components can maintain tack in environments ranging from -40°C to 80°C and exhibit excellent creep resistance, reducing adhesive layer loosening caused by temperature changes or prolonged load-bearing. Furthermore, the adhesive needs to have rapid curing properties to shorten the waiting time after disassembly and reassembly. However, excessively rapid curing may cause internal stress concentration; therefore, the application time must be adjusted according to the ambient temperature to ensure full cross-linking of the adhesive layer.

The surface treatment of the rim and tire directly affects the bonding quality. After repeated disassembly and assembly, adhesive residue or an oxide layer may remain on the rim surface. This requires mechanical grinding to remove the old adhesive layer and cleaning with solvents such as acetone until free of oil and rust. The inner wall of the tire also needs to be ground to a uniform roughness to enhance adhesive penetration. If the rim deformation exceeds 0.5mm, it needs to be corrected or replaced to avoid excessive gaps in the bonding surfaces. For aluminum alloy rims, avoid using acidic cleaners to prevent corrosion that could reduce adhesion.

Proper operating procedures during disassembly and assembly are crucial to avoiding damage. When disassembling, use a special pry bar to apply force evenly from the tire edge, avoiding excessive force at a single point that could deform the rim or tear the tire. During installation, align the tire with the center of the rim and slowly rotate and press it in, preventing misalignment that could cause localized stress concentration. If using a hydraulic tire press, the pressure must be controlled within the specified range to avoid rim cracks or tire deformation due to excessive pressure. For large trailer tires, a segmented pressing method is recommended: press in one side first, then rotate 180° and press in the other side to balance the force.

After multiple disassembly and reassembly, the thickness of the adhesive layer needs to be more strictly controlled. The initial adhesive layer thickness is typically 1-2mm, but repeated disassembly and reassembly can lead to uneven thickness of the new adhesive layer due to residual old adhesive. In this case, the old adhesive must be thoroughly removed, and new adhesive must be applied to ensure a consistent thickness. If the gap between the rim and tire increases due to wear, it can be adjusted by adding elastic shims, but the shim material must be compatible with the adhesive to avoid chemical corrosion.

Environmental factors have a significant impact on the bonding effect. High temperatures accelerate adhesive aging, leading to decreased adhesion; low temperatures may make the adhesive layer brittle and reduce impact resistance. Therefore, the ambient temperature during construction should be controlled between 15-35℃, and the humidity below 70%. If working outdoors, avoid rainy days or periods of high temperature, and cover the bonded area with a protective cover to prevent dust or moisture intrusion.

Regular inspection and maintenance are important means to extend the life of the adhesive layer. It is recommended to check the adhesion between the tire and rim every 3 months, focusing on whether the adhesive layer is cracked, bubbly, or detached. If any loosening is found, it should be cleaned and re-bonded promptly to prevent the problem from worsening. For trailer tires that bear heavy loads for extended periods, a protective agent can be applied periodically to form a protective film, reducing the corrosion of the adhesive layer by ultraviolet rays, oil, and other contaminants.

The repeated assembly and disassembly of trailer-bonded solid tires requires scientific management. From material selection and process control to post-assembly maintenance, each step must be strictly controlled. By optimizing operating procedures, strengthening environmental control, and conducting regular inspections, the reliability of adhesion can be significantly improved, reducing the safety risks caused by tire detachment and ensuring the long-term stable operation of the trailer.