What causes under-vulcanization during the vulcanization process of bonded solid tires and how to optimize process control?

Release Time : 2025-10-20

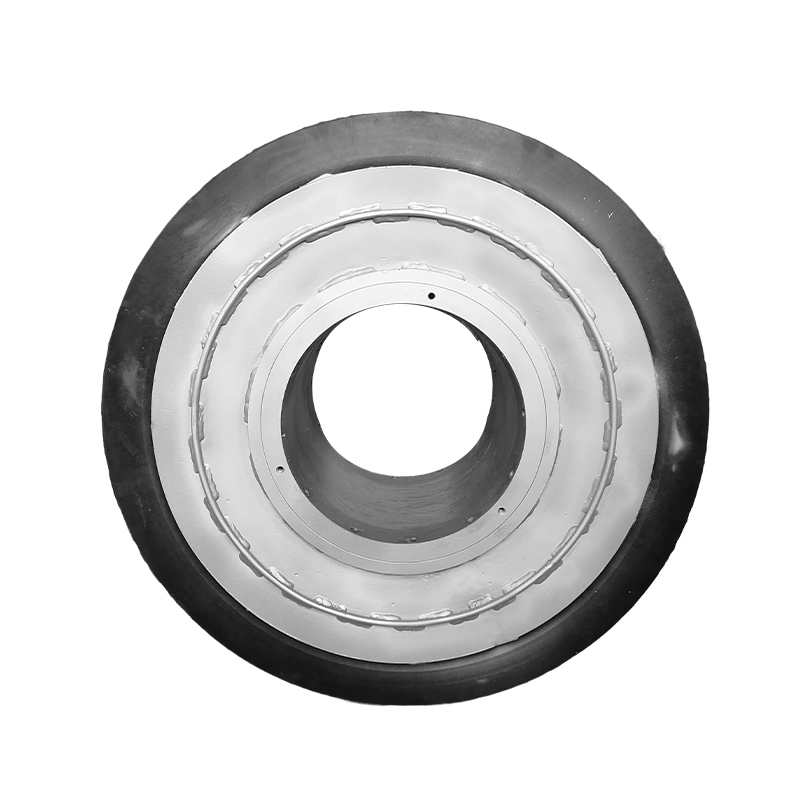

Undercure during the vulcanization process of bonded solid tires directly impacts their physical properties and service life. This can manifest as low rubber hardness, insufficient tensile strength, surface stickiness, or the formation of honeycomb-like pores. In severe cases, this can even lead to material delamination. The core cause of this problem can be attributed to deficiencies in the vulcanization process control, requiring analysis from three perspectives: equipment status, process parameters, and material properties.

Inadequate equipment sealing is a direct contributing factor to undercure. During the vulcanization process, gaps between the bladder and the steel ring, aging seals, or loose connecting screws can all lead to steam or hot water seeping into the tire bead, causing a localized temperature drop. For example, if the bladder opening is missing glue or exhibits spongy defects, the steel ring cannot be fully locked in place, leading to leakage of the vulcanization medium and directly impairing heat transfer efficiency. Furthermore, leakage from the water cylinder in the flexible mold control mechanism and mixing of power water into the tire bead area within the mold can disrupt the vulcanization reaction through temperature fluctuations, potentially creating the risk of undercure.

Process parameter fluctuations have a systematic impact on vulcanization quality. Coordinated control of vulcanization temperature, pressure, and time is crucial. Temperature deviations from the standard range can lead to insufficient crosslinking density. For example, if the pressure during the curing stage is too low, trapped air between the bladder wall and the inner wall of the tire blank cannot be expelled, forming an insulating layer that hinders heat transfer. Insufficient curing time prevents sufficient crosslinking of the rubber molecules, resulting in reduced tensile strength and wear resistance. Oversights in process execution are also crucial. For example, repeated vacuum curing when the tire blank is improperly loaded into the mold can damage the interface between the rubber and the carcass, creating conditions for undercure.

Material properties and process compatibility are the underlying causes of undercure. Poor quality innerliner rubber, such as the presence of lumps or cooked particles, can lead to undercure due to localized uneven heat conduction. Low Mooney viscosity or insufficient curing time can result in excessive tensile deformation during molding, leading to lower temperatures in stress-concentrated areas during curing. Improper formulation design, such as excessively high innerliner rubber content, can lead to bleed-through due to varying curing rates, further weakening the carcass' structural strength. Furthermore, excessive use of release agent or incomplete drying can vaporize during vulcanization, forming pores and exacerbating undervulcanization.

Optimizing process control requires a foundation of equipment maintenance. Regularly inspect the wear of the bladder, steel rings, and seals, and promptly replace aging components to ensure that assembly clearances meet standards. Modify the seals on the flexible mold operating mechanism to prevent water leakage and mold contamination. Furthermore, establish an equipment preheating and calibration system, and perform temperature uniformity checks on the mold and hot platen before vulcanization to avoid undervulcanization caused by local temperature differences.

Precise control of process parameters is key to addressing undervulcanization. Sensors monitor vulcanization temperature, pressure, and time in real time, and dynamically adjust thresholds based on material properties. For example, a staged heating process can be employed: initially using a lower temperature to promote rubber flow, then increasing the temperature in the middle to accelerate the crosslinking reaction, and finally maintaining the temperature to ensure complete vulcanization. During the finalization phase, pressurized exhaust is implemented to eliminate air pockets between the rubber and the frame material through repeated inflation and deflation.

Material management and formulation optimization must be integrated throughout the entire production process. Strictly control the quality of the inner liner rubber compound and increase uniformity testing during the mixing process to prevent the inclusion of powder lumps or cooked particles. Adjust the Mooney viscosity and holding time of the rubber compound according to molding process requirements to reduce the risk of tensile deformation. When designing the formula, comprehensively consider the compatibility of the rubber compound's curing speed with the carcass material. Determine the optimal blending ratio through testing to prevent bleed-through.

Under-curing issues in bonded solid tires require systematic process improvements. From equipment sealing maintenance, dynamic control of process parameters, to in-depth adaptation of material properties, optimization at every stage must be supported by data-driven and process control. Companies can establish a curing process database to accumulate optimal parameter combinations for different materials and product specifications, forming standardized operating procedures and ultimately achieving consistent improvement in the curing quality of bonded solid tires.