Do bonded solid tires have ultra-high load-bearing capacity?

Release Time : 2025-10-08

In modern large-scale construction projects, from the construction of giant ships to the erection of cross-sea bridges, from the assembly of petrochemical platforms to the transfer of ultra-large modules, heavy transport equipment undertakes the daunting task of moving hundreds or even thousands of tons. These machines often operate in complex environments and irregular ground conditions, placing extreme demands on the reliability and load-bearing capacity of their travel systems. In this context, whether bonded solid tires, as a travel solution designed for extreme working conditions, can provide ultra-high load-bearing capacity and stably support the operation of extremely heavy equipment such as shipbuilding gantry cranes and heavy module transporters has become a key factor in determining project safety and efficiency.

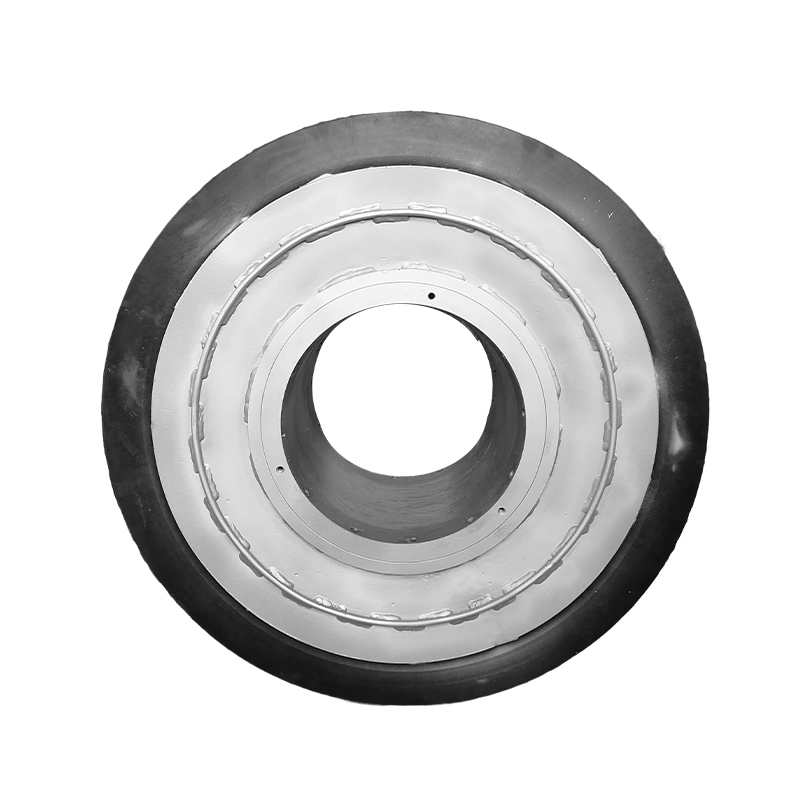

Traditional pneumatic tires rely on internal air pressure to support loads. While they offer some cushioning properties, they are highly susceptible to pressure imbalance, sidewall rupture, and even blowouts when operating with heavy loads. A tire failure during operation can not only cause equipment to overturn and cargo to be damaged, but can also potentially lead to serious safety accidents. Bonded solid tires, on the other hand, feature a solid, integral structure with no internal air cavity, relying solely on the physical compression of their high-density elastic material to withstand the immense pressure. This structure fundamentally eliminates the risk of tire blowouts, ensuring they maintain their shape stability under extreme loads. Whether statically bearing or in dynamic operation, solid tires evenly distribute the equipment's weight across the entire contact patch, avoiding localized stress concentrations and ensuring every movement is based on a solid foundation.

The ultra-high load-bearing capacity is achieved not only by the density and strength of the material, but also by the secure connection between the tire and the wheel. Bonded solid tires utilize an advanced chemical bonding process to tightly bond the solid tire carcass to the metal wheel hub, forming a single, load-bearing unit. This connection is far more reliable than mechanical fastening, effectively transmitting torque, withstanding lateral forces and impact loads, and preventing relative slippage or separation between the tire carcass and the wheel hub during heavy-load starting or braking. Even under high-stress conditions such as frequent starting and stopping, sudden braking, and operating on slopes, the bonded interface remains stable, ensuring continuous and safe power transmission.

At shipyards and bridge construction sites, the ground is often covered with welding slag, metal fragments, sand, gravel, and oil, making ordinary tires highly susceptible to punctures and wear. Solid tires, however, lack cavities, so even scratches or partial damage to their surfaces do not affect their overall load-bearing performance, allowing them to continue operating. This "scratch resistance" makes them particularly suitable for long-term service in harsh industrial environments. Furthermore, the material of solid tires is specially formulated to combine high hardness with moderate elasticity. This ensures load-bearing rigidity while providing a certain degree of cushioning on uneven surfaces, reducing impact on equipment structures and delicate components, and protecting valuable engineering equipment.

For equipment such as heavy modular transport vehicles (SPMTs) or gantry crane mobile platforms, which require precise alignment and stable support, solid tire deformation control is particularly critical. During prolonged static loads, solid tires avoid the "flat spots" or flattening that can occur with pneumatic tires, ensuring smooth operation upon restart. Their dimensional stability also ensures synchronization between multiple wheel groups, preventing uneven load distribution or skewed travel caused by individual tire deformation, thereby improving overall handling precision.

Furthermore, solid tires require no inflation and are maintenance-free, significantly reducing equipment operating costs and the risk of downtime. During tight construction schedules, there's no need to assign dedicated personnel to check tire pressure or replace tires, allowing equipment to remain operational and improving project efficiency.

In summary, bonded solid tires, thanks to their overall structural strength, advanced bonding process, and specially formulated materials designed for heavy loads, truly offer exceptional load-bearing capacity. They serve not only as the "legs" of heavy transport equipment but also as the "foundation" supporting the safe operation of the entire project. In fields such as shipbuilding, ship repair, and bridge construction, where reliability is paramount, choosing bonded solid tires infuses every move with a sense of stability and trust, allowing even the most formidable equipment to steadily advance under the weight of these sturdy wheels.

Traditional pneumatic tires rely on internal air pressure to support loads. While they offer some cushioning properties, they are highly susceptible to pressure imbalance, sidewall rupture, and even blowouts when operating with heavy loads. A tire failure during operation can not only cause equipment to overturn and cargo to be damaged, but can also potentially lead to serious safety accidents. Bonded solid tires, on the other hand, feature a solid, integral structure with no internal air cavity, relying solely on the physical compression of their high-density elastic material to withstand the immense pressure. This structure fundamentally eliminates the risk of tire blowouts, ensuring they maintain their shape stability under extreme loads. Whether statically bearing or in dynamic operation, solid tires evenly distribute the equipment's weight across the entire contact patch, avoiding localized stress concentrations and ensuring every movement is based on a solid foundation.

The ultra-high load-bearing capacity is achieved not only by the density and strength of the material, but also by the secure connection between the tire and the wheel. Bonded solid tires utilize an advanced chemical bonding process to tightly bond the solid tire carcass to the metal wheel hub, forming a single, load-bearing unit. This connection is far more reliable than mechanical fastening, effectively transmitting torque, withstanding lateral forces and impact loads, and preventing relative slippage or separation between the tire carcass and the wheel hub during heavy-load starting or braking. Even under high-stress conditions such as frequent starting and stopping, sudden braking, and operating on slopes, the bonded interface remains stable, ensuring continuous and safe power transmission.

At shipyards and bridge construction sites, the ground is often covered with welding slag, metal fragments, sand, gravel, and oil, making ordinary tires highly susceptible to punctures and wear. Solid tires, however, lack cavities, so even scratches or partial damage to their surfaces do not affect their overall load-bearing performance, allowing them to continue operating. This "scratch resistance" makes them particularly suitable for long-term service in harsh industrial environments. Furthermore, the material of solid tires is specially formulated to combine high hardness with moderate elasticity. This ensures load-bearing rigidity while providing a certain degree of cushioning on uneven surfaces, reducing impact on equipment structures and delicate components, and protecting valuable engineering equipment.

For equipment such as heavy modular transport vehicles (SPMTs) or gantry crane mobile platforms, which require precise alignment and stable support, solid tire deformation control is particularly critical. During prolonged static loads, solid tires avoid the "flat spots" or flattening that can occur with pneumatic tires, ensuring smooth operation upon restart. Their dimensional stability also ensures synchronization between multiple wheel groups, preventing uneven load distribution or skewed travel caused by individual tire deformation, thereby improving overall handling precision.

Furthermore, solid tires require no inflation and are maintenance-free, significantly reducing equipment operating costs and the risk of downtime. During tight construction schedules, there's no need to assign dedicated personnel to check tire pressure or replace tires, allowing equipment to remain operational and improving project efficiency.

In summary, bonded solid tires, thanks to their overall structural strength, advanced bonding process, and specially formulated materials designed for heavy loads, truly offer exceptional load-bearing capacity. They serve not only as the "legs" of heavy transport equipment but also as the "foundation" supporting the safe operation of the entire project. In fields such as shipbuilding, ship repair, and bridge construction, where reliability is paramount, choosing bonded solid tires infuses every move with a sense of stability and trust, allowing even the most formidable equipment to steadily advance under the weight of these sturdy wheels.