How do bonded solid tires maintain their structural integrity under the heavy loads of heavy-duty transport vehicles in shipyards?

Release Time : 2025-09-25

In the modern shipbuilding industry, transporting heavy components such as large hull sections, engine modules, and steel structures is a critical step in the production process. These tasks are typically handled by heavy-duty self-propelled module transporters or heavy-duty flatbed trucks. The complex operating environment and enormous loads place extremely high demands on tire performance. Traditional pneumatic tires are prone to safety hazards such as blowouts, punctures, and loose rims in such demanding conditions, seriously impacting production schedules and operational safety. Bonded solid tires, with their unique structural design and material advantages, are the ideal choice for heavy-duty transport vehicles in shipyards. They maintain structural integrity under long-term, heavy-duty conditions, ensuring efficient and safe transport operations.

1. High-strength rubber carcass provides excellent load-bearing capacity

The core of bonded solid tires lies in their fully solid construction. The carcass is integrally molded from a high-strength, highly elastic specialty rubber through a high-temperature and high-pressure vulcanization process. This rubber material boasts excellent compressive strength and deformation resistance, maintaining its shape even under sustained loads of tens or even hundreds of tons without sagging or collapsing due to localized stress concentrations. Unlike pneumatic tires, which rely on air pressure for support, solid tires rely on the inherent physical properties of the material to support their loads. This fundamentally avoids structural failure due to pressure loss, ensuring a stable contact patch and force distribution during heavy-duty operation.

2. High-Strength Bonding Technology Between the Metal Hub and the Rubber Layer

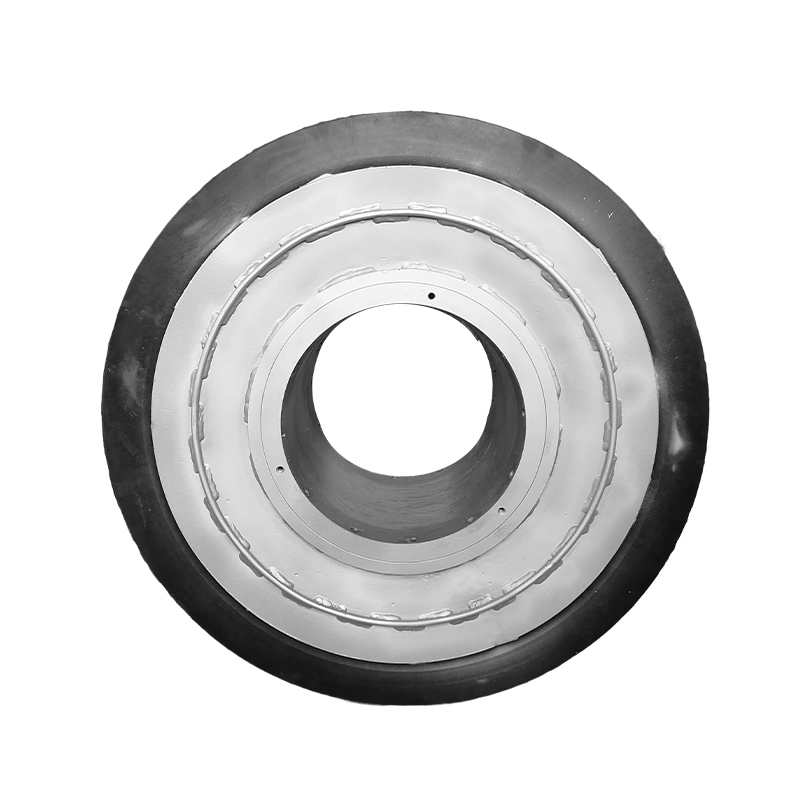

The key to bonded solid tires lies in the secure bond between the rubber carcass and the metal hub. During the manufacturing process, the precision-treated steel hub and unvulcanized rubber are simultaneously vulcanized at high temperatures in a mold, forming a dual chemical and mechanical bond between the rubber molecules and the hub surface. This one-piece bonded structure offers exceptional shear strength and peel resistance, effectively withstanding the torsional and impact forces associated with frequent starts and stops, sharp turns, and bumps during transportation. Even under long-term, heavy-duty cyclic loading, delamination, slippage, or hollowing are avoided, ensuring consistent structural integrity and functional coordination between the tire and wheel.

3. Puncture and Cut Resistance, Suitable for Complex Operating Environments

Shipyard floors are often contaminated by foreign matter such as welding slag, metal fragments, sharp bolts, and rough flooring, which can easily damage tires. The solid rubber construction of bonded solid tires completely eliminates the risk of punctures. Even scratches or cuts on the surface will not cause internal structural failure or gas leakage. The outer rubber layer is specially formulated to provide excellent wear, tear, and aging resistance, providing long-term resistance to oil, chemicals, and seawater splash, maintaining stable performance. This "maintenance-free" feature significantly reduces downtime caused by tire damage and significantly improves equipment utilization.

4. Optimized Structural Design for Stress Dispersion and Shock Absorption

Despite their solid construction, modern bonded solid tires are designed with vibration damping in mind. Some high-end products utilize a layered structure or internal stress relief grooves to generate subtle elastic deformation during impact, absorbing some of the vibration energy and reducing impact on the transport vehicle and equipment. Furthermore, the tire's cross-sectional shape and contact patch profile have been optimized to ensure even load distribution across the entire contact patch, preventing localized stresses that could lead to material fatigue or wheel deformation, further enhancing overall structural durability.

5. Simplified Installation and Maintenance-Free Design for Enhanced Operational Reliability

Bonded solid tires utilize standard bolts for installation, requiring no inflation equipment or specialized tools, making replacement quick and easy. Once in service, there's no need for regular pressure checks, tire repairs, or inner tube replacements, eliminating the maintenance burden associated with traditional tires. This "install-and-play, long-term reliability" feature is ideally suited to the high-intensity, continuous production demands of shipyards, effectively reducing operating costs and improving productivity.

Bonded solid tires, with their high-strength rubber carcass, advanced bonding process, superior damage resistance, and scientific structural design, demonstrate unparalleled structural integrity under the extreme, heavy-duty conditions of heavy-duty transport vehicles in shipyards. They not only ensure safe and stable transport operations, but also create significant economic benefits for shipbuilding companies with their exceptionally long service life and maintenance-free design.

1. High-strength rubber carcass provides excellent load-bearing capacity

The core of bonded solid tires lies in their fully solid construction. The carcass is integrally molded from a high-strength, highly elastic specialty rubber through a high-temperature and high-pressure vulcanization process. This rubber material boasts excellent compressive strength and deformation resistance, maintaining its shape even under sustained loads of tens or even hundreds of tons without sagging or collapsing due to localized stress concentrations. Unlike pneumatic tires, which rely on air pressure for support, solid tires rely on the inherent physical properties of the material to support their loads. This fundamentally avoids structural failure due to pressure loss, ensuring a stable contact patch and force distribution during heavy-duty operation.

2. High-Strength Bonding Technology Between the Metal Hub and the Rubber Layer

The key to bonded solid tires lies in the secure bond between the rubber carcass and the metal hub. During the manufacturing process, the precision-treated steel hub and unvulcanized rubber are simultaneously vulcanized at high temperatures in a mold, forming a dual chemical and mechanical bond between the rubber molecules and the hub surface. This one-piece bonded structure offers exceptional shear strength and peel resistance, effectively withstanding the torsional and impact forces associated with frequent starts and stops, sharp turns, and bumps during transportation. Even under long-term, heavy-duty cyclic loading, delamination, slippage, or hollowing are avoided, ensuring consistent structural integrity and functional coordination between the tire and wheel.

3. Puncture and Cut Resistance, Suitable for Complex Operating Environments

Shipyard floors are often contaminated by foreign matter such as welding slag, metal fragments, sharp bolts, and rough flooring, which can easily damage tires. The solid rubber construction of bonded solid tires completely eliminates the risk of punctures. Even scratches or cuts on the surface will not cause internal structural failure or gas leakage. The outer rubber layer is specially formulated to provide excellent wear, tear, and aging resistance, providing long-term resistance to oil, chemicals, and seawater splash, maintaining stable performance. This "maintenance-free" feature significantly reduces downtime caused by tire damage and significantly improves equipment utilization.

4. Optimized Structural Design for Stress Dispersion and Shock Absorption

Despite their solid construction, modern bonded solid tires are designed with vibration damping in mind. Some high-end products utilize a layered structure or internal stress relief grooves to generate subtle elastic deformation during impact, absorbing some of the vibration energy and reducing impact on the transport vehicle and equipment. Furthermore, the tire's cross-sectional shape and contact patch profile have been optimized to ensure even load distribution across the entire contact patch, preventing localized stresses that could lead to material fatigue or wheel deformation, further enhancing overall structural durability.

5. Simplified Installation and Maintenance-Free Design for Enhanced Operational Reliability

Bonded solid tires utilize standard bolts for installation, requiring no inflation equipment or specialized tools, making replacement quick and easy. Once in service, there's no need for regular pressure checks, tire repairs, or inner tube replacements, eliminating the maintenance burden associated with traditional tires. This "install-and-play, long-term reliability" feature is ideally suited to the high-intensity, continuous production demands of shipyards, effectively reducing operating costs and improving productivity.

Bonded solid tires, with their high-strength rubber carcass, advanced bonding process, superior damage resistance, and scientific structural design, demonstrate unparalleled structural integrity under the extreme, heavy-duty conditions of heavy-duty transport vehicles in shipyards. They not only ensure safe and stable transport operations, but also create significant economic benefits for shipbuilding companies with their exceptionally long service life and maintenance-free design.