How do bonded solid tires improve reach stackers' operational stability in complex yard conditions?

Release Time : 2025-09-11

In modern ports, logistics yards, and heavy industrial operations, reach stackers, as core equipment for container handling, operate constantly under complex and changing road conditions—uneven surfaces, scattered gravel, scattered metal fragments, scorching temperatures, and frequent heavy-load starting, stopping, and turning maneuvers. These conditions place extremely high demands on tires' load-bearing capacity, durability, and operational stability. While traditional pneumatic tires offer some shock absorption, they are prone to punctures and cuts, leading to blowouts or rim damage. This not only impacts operational efficiency but also poses serious safety risks. Bonded solid tires, with their unique structural design and material engineering, are becoming an ideal choice for reach stackers operating in complex conditions, significantly improving operational stability and overall reliability.

1. Solid Structure: Eliminates Sudden Failures, Ensuring Continuous and Stable Operation

Bonded solid tires are made of high-strength, highly elastic synthetic rubber through a specialized vulcanization process. They have no internal air cavities and require no inflation, fundamentally preventing sudden failures such as leaks and blowouts caused by sharp objects. In the debris common in storage yards, including rebar, sheet metal, and gravel, solid tires demonstrate exceptional puncture and cut resistance. Even minor surface scratches maintain their structural integrity and load-bearing capacity. This "never-blowout" feature ensures that reach stackers will not experience sudden downtime due to tire problems during all-weather, high-intensity operations, significantly enhancing operational continuity and stability.

2. High Load Capacity and Uniform Ground Contact: Enhanced Grip and Anti-Slip Performance

Bonded solid tires feature a dense carcass and a sturdy structure, offering exceptional load capacity and easily handling the heavy loads of reach stackers fully loaded with 40-foot containers. Its larger contact patch compared to pneumatic tires of similar specifications allows for more even pressure distribution, effectively reducing the specific ground pressure and minimizing the risk of sinking on soft or uneven surfaces. This larger contact patch also provides enhanced friction and grip, especially on slippery or dusty yard surfaces during rainy weather. It effectively prevents slipping, sliding, and spinning, improving operational stability during starting, braking, and steering, and ensuring safe operation.

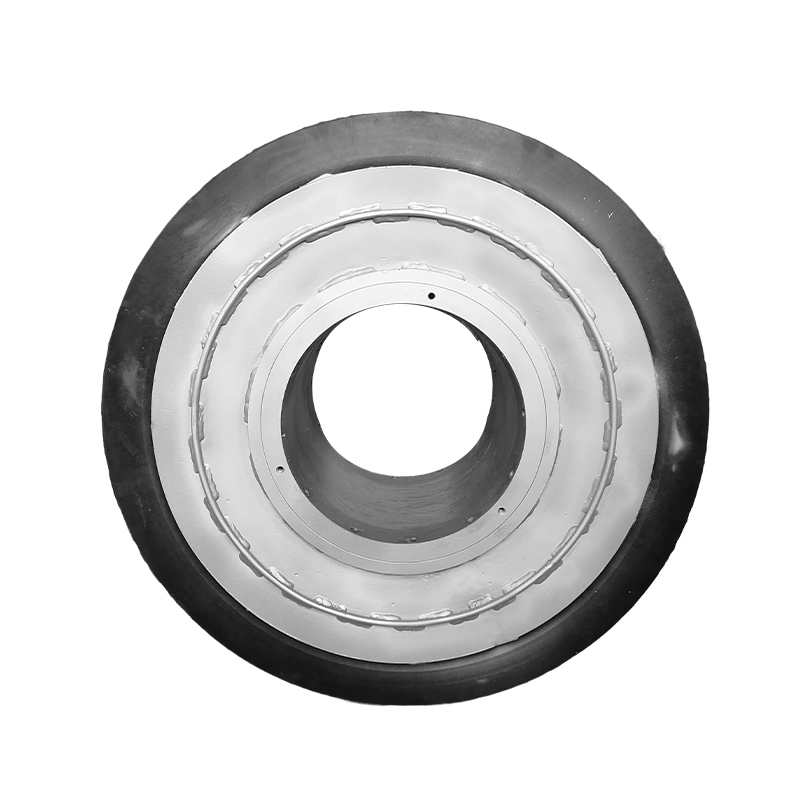

3. Enhanced Bonding: Ensures a secure bond between the tire and rim, eliminating the risk of delamination.

Bonding is a key technical feature of this solid tire. The tire's inner layer is secured to the metal rim using a dual-action, high-strength industrial adhesive and mechanical locking mechanism. This precise bonding is achieved under high temperature and high pressure, creating a solid, integrated unit. This structure significantly enhances the tire's torsional and shear resistance during high-speed driving, sharp turns, or downhill descents with heavy loads, effectively preventing the bead unseating and slippage that can occur with traditional press-fit solid tires. Even during frequent steering and lateral loads in reach stacker operations, bonded solid tires maintain a stable fit, ensuring efficient power transmission and precise tracking.

4. Excellent Shock Absorption and Cushioning Design: Balancing Stability and Operator Comfort

Despite their solid construction, modern bonded solid tires are designed with vibration damping in mind. Their multi-layered composite structure—a highly wear-resistant rubber outer layer, an elastic cushioning layer in the middle, and a high-strength support inner layer—effectively absorbs ground impact energy and reduces vibration transmission to the vehicle body. This structure ensures load-bearing capacity while enhancing driving comfort and reducing driver fatigue. It also helps protect the vehicle's delicate electronic components and hydraulic systems, further improving overall operational stability and reliability.

5. Maintenance-Free: Reduces human intervention and enhances system stability

Bonded solid tires require no inflation, regular pressure checks, or tire repairs or inner tube replacement, completely eliminating the maintenance associated with traditional tires. This maintenance-free feature not only significantly reduces maintenance costs and labor, but also eliminates stability risks such as tire overheating, bead unseating, and abnormal wear caused by human error (e.g., insufficient air pressure). This allows for extended periods of continuous operation, significantly improving availability and making it particularly suitable for the 24/7, high-intensity operations of modern yards.

In summary, bonded solid tires, with their comprehensive advantages of explosion and puncture resistance, high load capacity, strong adhesion, optimized vibration damping, and maintenance-free operation, comprehensively enhance the operational stability of reach stackers in complex yard conditions. More than just a tire replacement, it represents a comprehensive upgrade in equipment reliability and operational safety, providing a solid foundation for efficient, safe, and sustainable port logistics operations.

1. Solid Structure: Eliminates Sudden Failures, Ensuring Continuous and Stable Operation

Bonded solid tires are made of high-strength, highly elastic synthetic rubber through a specialized vulcanization process. They have no internal air cavities and require no inflation, fundamentally preventing sudden failures such as leaks and blowouts caused by sharp objects. In the debris common in storage yards, including rebar, sheet metal, and gravel, solid tires demonstrate exceptional puncture and cut resistance. Even minor surface scratches maintain their structural integrity and load-bearing capacity. This "never-blowout" feature ensures that reach stackers will not experience sudden downtime due to tire problems during all-weather, high-intensity operations, significantly enhancing operational continuity and stability.

2. High Load Capacity and Uniform Ground Contact: Enhanced Grip and Anti-Slip Performance

Bonded solid tires feature a dense carcass and a sturdy structure, offering exceptional load capacity and easily handling the heavy loads of reach stackers fully loaded with 40-foot containers. Its larger contact patch compared to pneumatic tires of similar specifications allows for more even pressure distribution, effectively reducing the specific ground pressure and minimizing the risk of sinking on soft or uneven surfaces. This larger contact patch also provides enhanced friction and grip, especially on slippery or dusty yard surfaces during rainy weather. It effectively prevents slipping, sliding, and spinning, improving operational stability during starting, braking, and steering, and ensuring safe operation.

3. Enhanced Bonding: Ensures a secure bond between the tire and rim, eliminating the risk of delamination.

Bonding is a key technical feature of this solid tire. The tire's inner layer is secured to the metal rim using a dual-action, high-strength industrial adhesive and mechanical locking mechanism. This precise bonding is achieved under high temperature and high pressure, creating a solid, integrated unit. This structure significantly enhances the tire's torsional and shear resistance during high-speed driving, sharp turns, or downhill descents with heavy loads, effectively preventing the bead unseating and slippage that can occur with traditional press-fit solid tires. Even during frequent steering and lateral loads in reach stacker operations, bonded solid tires maintain a stable fit, ensuring efficient power transmission and precise tracking.

4. Excellent Shock Absorption and Cushioning Design: Balancing Stability and Operator Comfort

Despite their solid construction, modern bonded solid tires are designed with vibration damping in mind. Their multi-layered composite structure—a highly wear-resistant rubber outer layer, an elastic cushioning layer in the middle, and a high-strength support inner layer—effectively absorbs ground impact energy and reduces vibration transmission to the vehicle body. This structure ensures load-bearing capacity while enhancing driving comfort and reducing driver fatigue. It also helps protect the vehicle's delicate electronic components and hydraulic systems, further improving overall operational stability and reliability.

5. Maintenance-Free: Reduces human intervention and enhances system stability

Bonded solid tires require no inflation, regular pressure checks, or tire repairs or inner tube replacement, completely eliminating the maintenance associated with traditional tires. This maintenance-free feature not only significantly reduces maintenance costs and labor, but also eliminates stability risks such as tire overheating, bead unseating, and abnormal wear caused by human error (e.g., insufficient air pressure). This allows for extended periods of continuous operation, significantly improving availability and making it particularly suitable for the 24/7, high-intensity operations of modern yards.

In summary, bonded solid tires, with their comprehensive advantages of explosion and puncture resistance, high load capacity, strong adhesion, optimized vibration damping, and maintenance-free operation, comprehensively enhance the operational stability of reach stackers in complex yard conditions. More than just a tire replacement, it represents a comprehensive upgrade in equipment reliability and operational safety, providing a solid foundation for efficient, safe, and sustainable port logistics operations.