No blowouts, zero maintenance! How do solid tires keep RTGs running "forever"?

Release Time : 2025-08-26

In heavy-duty operations such as ports and logistics parks, tire-tyred gantry cranes (RTGs) and reach stackers are core equipment, and their operational efficiency and safety are directly linked to overall operational effectiveness. However, traditional pneumatic tires frequently suffer from blowouts, cuts, and rim damage under complex operating conditions, increasing equipment downtime and posing safety risks. Against this backdrop, bonded solid tires, with their all-inclusive structure, high-strength rubber material, and maintenance-free nature, are becoming a preferred solution for industry upgrades, bringing about a revolutionary change in the operation and maintenance of heavy equipment.

1. All-inclusive Solid Structure: From "Passive Protection" to "Active Immunity"

1. All-inclusive Solid Structure: From "Passive Protection" to "Active Immunity"

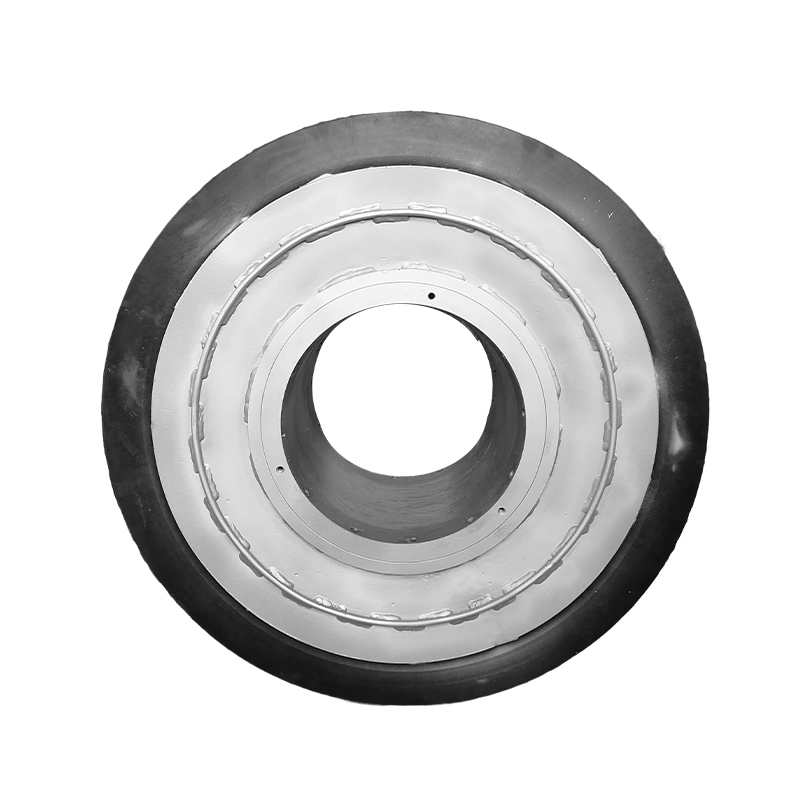

The "air pressure + cord ply" structure of traditional pneumatic tires is highly susceptible to sudden pressure drops due to localized damage when exposed to sharp rocks, metal fragments, or heavy loads. This can lead to serious accidents such as blowouts or rim retaining rings being blown off. Bonded solid tires feature a fully enclosed design with a 1800x600 diameter tire body molded from high-strength rubber. They are tubeless and airless, completely eliminating the safety risks associated with air pressure.

Punch and Cut Resistance: The solid rubber material can withstand punctures from sharp objects over 10 cm in diameter. Even surface scratches maintain structural integrity, preventing the risk of equipment tipping over due to tire damage.

Blowout-Resistant Design: The tire body, unsupported by air pressure, eliminates the risk of leaks or blowouts, making it particularly suitable for harsh environments like port container yards and steel mills, where large amounts of metal debris are present.

Rim Protection: The fully enclosed structure completely encloses the rim, preventing deformation caused by heavy loads or lateral forces, extending its service life to over five years.

II. Maintenance-Free: From "Frequent Maintenance" to "Long-Term Operation"

Traditional tires require regular pressure checks, leak repairs, and tread replacement. Bonded solid tires, through innovative materials and processes, offer a "fit and forget" maintenance-free experience.

Easy Installation: The standardized bolt-on design eliminates the need for specialized inflation equipment or dynamic balancing. Single tire replacement time is reduced from two hours for traditional tires to 20 minutes, significantly reducing equipment downtime.

Zero Maintenance Cost: No need to refill air pressure, repair treads, or replace inner tubes, saving a single RTG over 30,000 yuan in tire maintenance costs annually.

Extremely Long Lifespan: Under equivalent operating conditions, solid tires offer a lifespan over three times that of pneumatic tires. For example, a port RTG with an annual operating mileage of approximately 20,000 kilometers can provide stable service for over five years, while pneumatic tires require replacement every 1.5 years.

III. Dual Optimization of Efficiency and Cost: From "Reactive Response" to "Proactive Value-Added"

The use of bonded solid tires not only improves equipment safety but also directly drives profit growth by reducing operational complexity and costs.

Improved Equipment Utilization: The maintenance-free feature increases equipment availability to over 98%, eliminating operational interruptions due to tire failures. This is particularly suitable for ports operating 24/7. Reduced Overall Costs: Taking a single RTG as an example, the full lifecycle cost (including purchase, installation, and maintenance) of solid tires is 40% lower than that of pneumatic tires, saving over 500,000 yuan over a 10-year lifecycle.

Suitable for High-Intensity Working Conditions: The 1800*600 tire is designed specifically for heavy equipment, with a single tire load capacity exceeding 20 tons, easily handling the full-load lifting of reach stackers and the cross-bay maneuvering of RTGs.

IV. Industry Application Cases: From "Pilot Verification" to "Scaled-Up"

An international container terminal piloted the replacement of three RTG tires with bonded solid tires in 2022 and achieved significant results:

Improved Safety: No equipment downtime or safety incidents due to tire failure occurred within one year.

Optimized Operational and Maintenance Efficiency: Tire maintenance man-hours were reduced by 75%, allowing maintenance personnel to be redirected to other equipment support tasks.

Significant Economic Benefits: Annual cost savings per unit exceed 80,000 yuan, with a payback period of just 1.2 years. The terminal has currently implemented solid tires on all 20 RTGs and 10 reach stackers, with plans to gradually expand their use to other equipment, including forklifts and forklifts.

Using innovative tire technology to revolutionize heavy equipment operations and maintenance

Bonded solid tires redefine the performance standard for heavy equipment tires through structural innovation and material upgrades. Their all-inclusive design, maintenance-free operation, and exceptionally long lifespan not only address the safety and efficiency challenges of traditional tires but also create significant economic value for businesses by reducing overall lifecycle costs. With the accelerating trend toward automation and intelligent port development, solid tires will become standard equipment for equipment like RTGs and reach stackers, helping the industry move towards greater safety, efficiency, and sustainability.

The "air pressure + cord ply" structure of traditional pneumatic tires is highly susceptible to sudden pressure drops due to localized damage when exposed to sharp rocks, metal fragments, or heavy loads. This can lead to serious accidents such as blowouts or rim retaining rings being blown off. Bonded solid tires feature a fully enclosed design with a 1800x600 diameter tire body molded from high-strength rubber. They are tubeless and airless, completely eliminating the safety risks associated with air pressure.

Punch and Cut Resistance: The solid rubber material can withstand punctures from sharp objects over 10 cm in diameter. Even surface scratches maintain structural integrity, preventing the risk of equipment tipping over due to tire damage.

Blowout-Resistant Design: The tire body, unsupported by air pressure, eliminates the risk of leaks or blowouts, making it particularly suitable for harsh environments like port container yards and steel mills, where large amounts of metal debris are present.

Rim Protection: The fully enclosed structure completely encloses the rim, preventing deformation caused by heavy loads or lateral forces, extending its service life to over five years.

II. Maintenance-Free: From "Frequent Maintenance" to "Long-Term Operation"

Traditional tires require regular pressure checks, leak repairs, and tread replacement. Bonded solid tires, through innovative materials and processes, offer a "fit and forget" maintenance-free experience.

Easy Installation: The standardized bolt-on design eliminates the need for specialized inflation equipment or dynamic balancing. Single tire replacement time is reduced from two hours for traditional tires to 20 minutes, significantly reducing equipment downtime.

Zero Maintenance Cost: No need to refill air pressure, repair treads, or replace inner tubes, saving a single RTG over 30,000 yuan in tire maintenance costs annually.

Extremely Long Lifespan: Under equivalent operating conditions, solid tires offer a lifespan over three times that of pneumatic tires. For example, a port RTG with an annual operating mileage of approximately 20,000 kilometers can provide stable service for over five years, while pneumatic tires require replacement every 1.5 years.

III. Dual Optimization of Efficiency and Cost: From "Reactive Response" to "Proactive Value-Added"

The use of bonded solid tires not only improves equipment safety but also directly drives profit growth by reducing operational complexity and costs.

Improved Equipment Utilization: The maintenance-free feature increases equipment availability to over 98%, eliminating operational interruptions due to tire failures. This is particularly suitable for ports operating 24/7. Reduced Overall Costs: Taking a single RTG as an example, the full lifecycle cost (including purchase, installation, and maintenance) of solid tires is 40% lower than that of pneumatic tires, saving over 500,000 yuan over a 10-year lifecycle.

Suitable for High-Intensity Working Conditions: The 1800*600 tire is designed specifically for heavy equipment, with a single tire load capacity exceeding 20 tons, easily handling the full-load lifting of reach stackers and the cross-bay maneuvering of RTGs.

IV. Industry Application Cases: From "Pilot Verification" to "Scaled-Up"

An international container terminal piloted the replacement of three RTG tires with bonded solid tires in 2022 and achieved significant results:

Improved Safety: No equipment downtime or safety incidents due to tire failure occurred within one year.

Optimized Operational and Maintenance Efficiency: Tire maintenance man-hours were reduced by 75%, allowing maintenance personnel to be redirected to other equipment support tasks.

Significant Economic Benefits: Annual cost savings per unit exceed 80,000 yuan, with a payback period of just 1.2 years. The terminal has currently implemented solid tires on all 20 RTGs and 10 reach stackers, with plans to gradually expand their use to other equipment, including forklifts and forklifts.

Using innovative tire technology to revolutionize heavy equipment operations and maintenance

Bonded solid tires redefine the performance standard for heavy equipment tires through structural innovation and material upgrades. Their all-inclusive design, maintenance-free operation, and exceptionally long lifespan not only address the safety and efficiency challenges of traditional tires but also create significant economic value for businesses by reducing overall lifecycle costs. With the accelerating trend toward automation and intelligent port development, solid tires will become standard equipment for equipment like RTGs and reach stackers, helping the industry move towards greater safety, efficiency, and sustainability.