How do bonded solid tires withstand the pressure of transporting hundreds of tons of ship modules in shipbuilding and ship repair operations?

Release Time : 2025-08-20

In modern shipbuilding and ship repair projects, the handling and transfer of large ship modules is a critical construction step. These modules often weigh hundreds of tons and require precise movement between docks, workshops, and piers using heavy-duty self-propelled module transporters (SPMTs) or specialized transport platforms. Traditional pneumatic tires struggle in this demanding environment due to their proneness to blowouts, frequent maintenance requirements, and limited load capacity. Bonded solid tires, with their superior structural design and material properties, are an ideal choice for heavy-duty transport, capable of stably carrying hundreds of tons and ensuring safe and efficient operations.

High-strength rubber carcass provides excellent load-bearing capacity

The core advantage of fully encased bonded solid tires lies in their one-piece, high-strength rubber carcass. Unlike pneumatic tires, which rely on internal air pressure for support, bonded solid tires rely entirely on their high-density, highly elastic specialty rubber material to bear the load. This specially formulated, vulcanized rubber possesses exceptionally high compressive strength and deformation resistance, ensuring structural stability under prolonged heavy loads without collapse or creep. Even under extreme operating conditions, carrying hundreds of tons of continuous load, the tire maintains even pressure distribution, ensuring smooth operation of the transport platform.

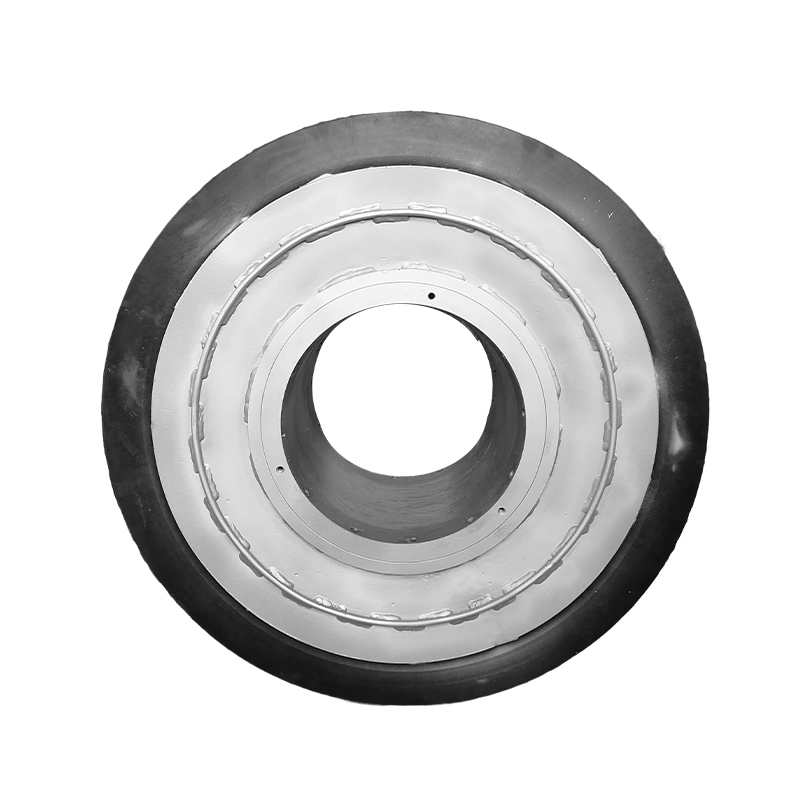

Composite structural design enhances overall rigidity and durability

High-end bonded solid tires typically utilize a composite "rubber + metal frame" construction. A high-strength steel core or metal hub is embedded within the tire, acting as a force transmission hub, evenly transferring load from the axle to the entire tire body. The outer layer is coated with multiple layers of wear-resistant and tear-resistant rubber, forming a robust protective layer. This construction not only enhances the tire's overall rigidity but also effectively prevents failures such as cracking and delamination during heavy-load starting, braking, or steering, ensuring long-term reliable operation.

The fully enclosed design eliminates the risk of tire blowouts and rim ejection

Shipbuilding sites are often littered with dangerous debris such as welding slag, metal fragments, and sharp components, which can easily puncture pneumatic tires, leading to sudden blowouts and even serious accidents such as rim ejection. Fully enclosed bonded solid tires, however, feature a completely solid construction with no air cavity or inner tube, fundamentally eliminating the risk of blowouts. Even scratches or localized wear on the surface will not affect overall load-bearing performance, significantly improving operational safety. They are particularly suitable for high-risk ship repair and hull assembly areas.

Excellent environmental resistance adapts to complex working conditions

Shipbuilding and ship repair environments are harsh, often subject to oil contamination, seawater corrosion, high-temperature welding, and extreme temperature fluctuations. Fully enclosed bonded solid tires are made of a special, oil-resistant, corrosion-resistant, and flame-retardant rubber material. They operate stably in temperatures ranging from -30°C to +80°C and are resistant to aging, hardening, or cracking. Their surface also features a superior non-slip texture, ensuring reliable grip even on slippery decks or inclined ramps. Maintenance-free design improves operational continuity

Bonded solid tires require no inflation, tire repairs, or regular pressure checks, truly ensuring "install-and-use, lifetime maintenance-free." This not only reduces equipment downtime, but also lowers maintenance costs and manpower. During the intense shipbuilding cycle, transport equipment can operate continuously around the clock, ensuring project progress.

Easy installation, suitable for heavy-duty transport platforms

All-inclusive bonded solid tires are typically bolted directly to the axle using standard flanges and bolts. Installation is simple and quick, requiring no specialized inflation equipment or complex tools. Their size and load rating can be customized to the specific needs of the transport platform, making them compatible with a wide range of heavy-duty module transporters, self-propelled hydraulic flatbed trucks, and other equipment.

In shipbuilding and ship repair operations, bonded solid tires, with their high-strength rubber carcass, explosion and puncture resistance, maintenance-free design, long life, and excellent load-bearing capacity, serve as the "iron feet" supporting the safe transfer of hundreds of tons of ship modules. They not only improve the reliability and safety of heavy-duty transport, but also promote the development of efficient and intelligent shipbuilding. In the modern industrial scene that pursues zero failure and high efficiency, bonded solid tires are playing an irreplaceable and key role.

High-strength rubber carcass provides excellent load-bearing capacity

The core advantage of fully encased bonded solid tires lies in their one-piece, high-strength rubber carcass. Unlike pneumatic tires, which rely on internal air pressure for support, bonded solid tires rely entirely on their high-density, highly elastic specialty rubber material to bear the load. This specially formulated, vulcanized rubber possesses exceptionally high compressive strength and deformation resistance, ensuring structural stability under prolonged heavy loads without collapse or creep. Even under extreme operating conditions, carrying hundreds of tons of continuous load, the tire maintains even pressure distribution, ensuring smooth operation of the transport platform.

Composite structural design enhances overall rigidity and durability

High-end bonded solid tires typically utilize a composite "rubber + metal frame" construction. A high-strength steel core or metal hub is embedded within the tire, acting as a force transmission hub, evenly transferring load from the axle to the entire tire body. The outer layer is coated with multiple layers of wear-resistant and tear-resistant rubber, forming a robust protective layer. This construction not only enhances the tire's overall rigidity but also effectively prevents failures such as cracking and delamination during heavy-load starting, braking, or steering, ensuring long-term reliable operation.

The fully enclosed design eliminates the risk of tire blowouts and rim ejection

Shipbuilding sites are often littered with dangerous debris such as welding slag, metal fragments, and sharp components, which can easily puncture pneumatic tires, leading to sudden blowouts and even serious accidents such as rim ejection. Fully enclosed bonded solid tires, however, feature a completely solid construction with no air cavity or inner tube, fundamentally eliminating the risk of blowouts. Even scratches or localized wear on the surface will not affect overall load-bearing performance, significantly improving operational safety. They are particularly suitable for high-risk ship repair and hull assembly areas.

Excellent environmental resistance adapts to complex working conditions

Shipbuilding and ship repair environments are harsh, often subject to oil contamination, seawater corrosion, high-temperature welding, and extreme temperature fluctuations. Fully enclosed bonded solid tires are made of a special, oil-resistant, corrosion-resistant, and flame-retardant rubber material. They operate stably in temperatures ranging from -30°C to +80°C and are resistant to aging, hardening, or cracking. Their surface also features a superior non-slip texture, ensuring reliable grip even on slippery decks or inclined ramps. Maintenance-free design improves operational continuity

Bonded solid tires require no inflation, tire repairs, or regular pressure checks, truly ensuring "install-and-use, lifetime maintenance-free." This not only reduces equipment downtime, but also lowers maintenance costs and manpower. During the intense shipbuilding cycle, transport equipment can operate continuously around the clock, ensuring project progress.

Easy installation, suitable for heavy-duty transport platforms

All-inclusive bonded solid tires are typically bolted directly to the axle using standard flanges and bolts. Installation is simple and quick, requiring no specialized inflation equipment or complex tools. Their size and load rating can be customized to the specific needs of the transport platform, making them compatible with a wide range of heavy-duty module transporters, self-propelled hydraulic flatbed trucks, and other equipment.

In shipbuilding and ship repair operations, bonded solid tires, with their high-strength rubber carcass, explosion and puncture resistance, maintenance-free design, long life, and excellent load-bearing capacity, serve as the "iron feet" supporting the safe transfer of hundreds of tons of ship modules. They not only improve the reliability and safety of heavy-duty transport, but also promote the development of efficient and intelligent shipbuilding. In the modern industrial scene that pursues zero failure and high efficiency, bonded solid tires are playing an irreplaceable and key role.